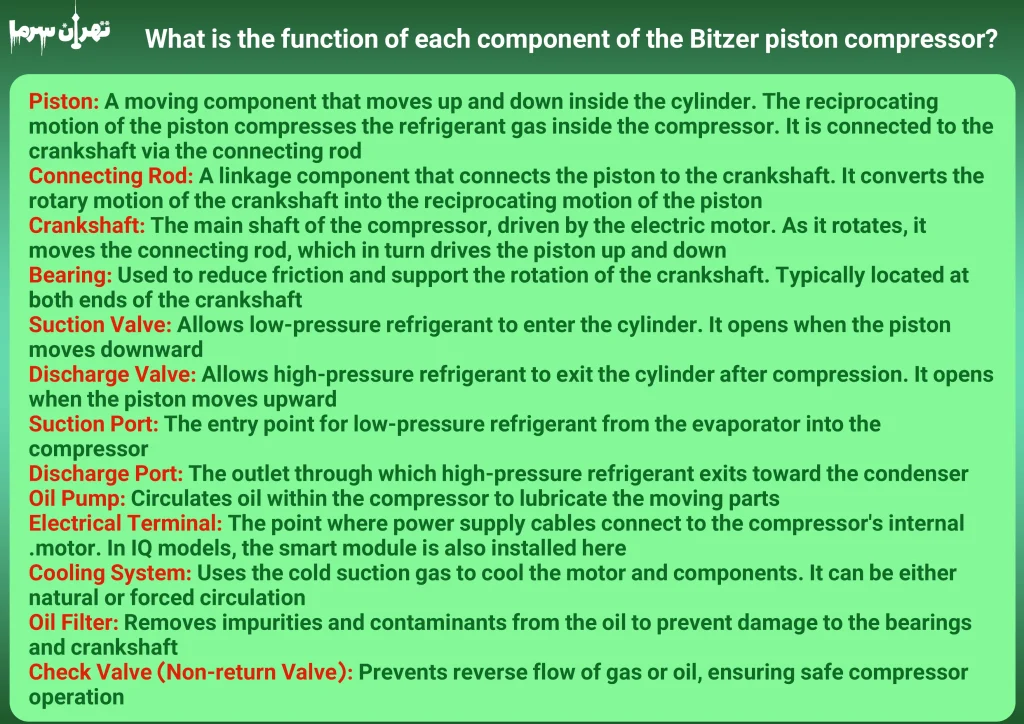

The Bitzer reciprocating compressor is recognized as one of the most advanced and reliable devices in the refrigeration and air conditioning sector. Leveraging precise engineering design and high-quality parts, it has secured a prominent position in cooling and heating systems, drawing attention from engineers and specialists thanks to its optimal performance, long durability, and energy-efficient operation.

A complete understanding of the constituent components of the Bitzer reciprocating compressor and the role of each is fundamental for successful operation, maintenance, and repair of these units, ensuring that refrigeration systems maintain stable and efficient performance.

At the core of this compressor, a set of highly precise mechanical parts perform the refrigerant gas compression process. The cylinder and piston, which are the main mechanical components, convert the refrigerant gas from low to high pressure by the reciprocating movement of the piston inside the cylinder.

This movement is driven by the crankshaft and connecting rod, which transform the rotary force of the electric motor into linear motion. The precision in manufacturing these parts and the selection of suitable materials significantly reduce friction, increase efficiency, and improve the compressor’s service life.

In addition to the mechanical parts, the refrigerant flow control system is precisely regulated by the suction and discharge valves. These valves are responsible for allowing refrigerant gas to enter the compressor chamber at the appropriate time and, after compression, directing it towards the cooling system.

The design and operation of these valves prevent backflow of the refrigerant and avoid any leakage or efficiency loss. Their role is crucial in maintaining pressure stability and protecting other components from mechanical damage.

The electric motor, acting as the driving heart of the Bitzer reciprocating compressor, provides the necessary power to drive the crankshaft and pistons. The build quality of this motor and its capability to withstand variable loads and diverse environmental conditions are key factors in ensuring continuous compressor operation. Alongside these, auxiliary components such as bearings, gaskets, and lubrication systems contribute to maintaining mechanical integrity and reducing wear, thereby preventing premature failure.

The integrated and coordinated design of all these components makes the Bitzer reciprocating compressor an efficient and reliable system capable of operating at maximum productivity under various working conditions. A thorough familiarity with these parts and their functions not only enables operators and technicians to quickly identify and resolve issues but also facilitates proper preventive maintenance, significantly extending equipment lifespan.

Consequently, this specialized knowledge not only helps preserve compressor performance but also plays an important role in optimizing energy consumption and reducing operational costs of refrigeration systems.

Detailed Operation of Each Component of the Bitzer Reciprocating Compressor and Its Role in the Compressor

The precise and coordinated operation of each component in the Bitzer reciprocating compressor forms the foundation for the device’s high efficiency and performance. Each part, according to its specific role, effectively and stably carries out a portion of the refrigerant compression process. In this section, the operation of each key compressor component and its impact on overall system performance are examined.

The piston, as the primary compression element, reduces the volume of the refrigerant gas and increases its pressure through its reciprocating movement inside the cylinder. This regular and precise motion ensures a uniform refrigerant flow and maintains pressure balance within the system. The role of the cylinder is to provide a durable and dimensionally precise chamber for the piston’s movement, resisting the alternating pressures and friction caused by contact between the piston and cylinder wall.

The crankshaft and connecting rod serve as intermediaries converting rotary motion into linear motion and play a vital role in the Bitzer reciprocating compressor. The crankshaft transmits the motor’s power into the reciprocating movement of the pistons through its rotation, while the connecting rod connects to the piston and applies this force precisely and evenly. The engineering design of these parts must allow them to withstand dynamic forces while minimizing wear and unwanted vibrations.

The suction and discharge valves control the refrigerant flow and must open and close very precisely to prevent gas backflow and maintain optimal refrigerant circulation in the cycle. These valves react quickly to pressure changes, ensuring that the gas enters the compressor chamber at the proper time and is directed to the condenser after compression. Proper functioning of these valves is highly important, as any malfunction can cause efficiency loss and increased energy consumption.

The electric motor in the Bitzer reciprocating compressor provides the necessary driving force and must be capable of handling variable working conditions. Proper motor operation ensures continuous and uninterrupted crankshaft rotation, which directly affects the overall compressor performance. Additionally, lubrication systems and bearings reduce friction and enhance smooth movement of moving parts, helping maintain the device’s health and longevity.

The coordination and optimal operation of each of these components enable the Bitzer reciprocating compressor to perform with maximum efficiency and minimal failure across various operating conditions. Familiarity with the detailed function of each part and understanding its role in the compressor provide a powerful tool for technicians and engineers to enhance maintenance and repairs, thereby maximizing system productivity.

Materials and Technologies Used in the Construction of Bitzer Reciprocating Compressor Components

The materials and technologies employed in manufacturing the components of the Bitzer reciprocating compressor play a decisive role in the quality, durability, and overall performance of the device. As a pioneer in the refrigeration industry, Bitzer utilizes advanced materials and modern manufacturing technologies to produce products that are not only mechanically strong and stable but also reliably perform under harsh and long-term operating conditions.

For the main mechanical parts such as pistons and cylinders, high-precision aluminum and steel alloys are typically used, providing both desirable mechanical strength and appropriate weight.

Special steel alloys subjected to precise heat treatment processes help increase hardness and wear resistance, thereby reducing friction between the piston and cylinder and significantly extending the parts’ service life. Additionally, advanced surface coatings, such as nitriding or chrome plating, are applied in some areas to enhance resistance against corrosion and wear.

In the crankshaft and connecting rods of the Bitzer reciprocating compressor, the use of high-carbon steels combined with specific heat treatments enables these parts to endure high dynamic forces and cyclic stresses. Precise machining and dynamic balancing technologies help reduce vibrations and improve the smoothness of motion, ultimately boosting the compressor’s efficiency.

The suction and discharge valves are also made from corrosion- and wear-resistant materials, as they are in direct contact with refrigerant gas and subject to frequent pressure changes. Their engineering design, employing advanced molding and machining technologies, increases operational accuracy and extends their lifespan.

Moreover, advanced lubrication systems—including specialized oils and optimized oil pump mechanisms—play a key role in reducing friction and preventing wear of moving components. Modern lubrication technologies are developed not only to minimize friction but also to effectively manage generated heat, preventing the compressor from overheating.

Strict quality control processes and the use of advanced testing and analysis equipment ensure that every component of the Bitzer reciprocating compressor is manufactured to the highest industrial standards and capable of stable long-term performance. This combination of quality materials and cutting-edge technologies is the main reason behind Bitzer compressors’ global success and the widespread trust consumers place in this reputable brand.

Maintenance and Troubleshooting Methods for Bitzer Reciprocating Compressor Components

Maintenance and troubleshooting of Bitzer reciprocating compressor components are of high importance to ensure optimal performance and long service life of the equipment. Regular and periodic inspections allow technicians to identify early signs of failure or performance degradation and prevent serious damages. Special attention during maintenance should be given to the lubrication system, bearing conditions, the health of suction and discharge valves, as well as detailed examination of pistons and cylinders.

Detection of unusual noises, pressure and temperature fluctuations, and changes in compressor performance can be critical indicators of faults in components, which can be diagnosed more precisely using specialized equipment. Successful troubleshooting requires a deep understanding of the operation of each part and their interactions, enabling the technician to analyze symptoms and technical data to pinpoint problems and propose appropriate solutions.

Furthermore, following the manufacturer’s standard guidelines and adhering to safety measures play important roles in preventing human errors and protecting equipment health. Implementing preventive maintenance and timely repairs not only avoids widespread failures but also optimizes energy consumption and reduces the operational costs of refrigeration systems.

Overall, precise and regular maintenance and troubleshooting of Bitzer reciprocating compressor components are the keys to achieving stable operation, extending equipment lifespan, and maintaining optimal efficiency over the long term.

Preventive Tips to Increase Lifespan and Reduce Failures of Bitzer Reciprocating Compressors

Each component of the Bitzer reciprocating compressor plays a vital and complementary role in the refrigerant compression process; the piston reduces gas volume and increases pressure by its reciprocating motion inside the cylinder, while the crankshaft and connecting rod convert the motor’s rotary force into linear motion, enabling piston movement.

The suction and discharge valves regulate refrigerant flow by precise opening and closing, preventing gas backflow and optimizing the compression process. The electric motor provides the necessary driving force, and the lubrication system reduces friction and protects moving parts, helping maintain compressor health and durability. Precise coordination of these components ensures that the Bitzer compressor operates stably with maximum efficiency and minimum wear under varying working conditions.

Choosing the Best Cold Storage Equipment with Tehran Sarma Engineering Company

Selecting the best equipment for cold storage construction is one of the most important stages in designing and implementing industrial and commercial cold rooms, directly impacting product preservation quality and overall system efficiency. Tehran Sarma Engineering Company, with years of specialized experience in designing and supplying advanced cold storage equipment, offers comprehensive solutions tailored to Iran’s climatic and environmental conditions.

By leveraging modern technologies and cooperating with reputable global brands, the company provides high-quality, durable equipment that ensures energy savings, optimal performance, and product safety.

Tehran Sarma’s expert consultation and continuous technical support simplify and secure the process of selecting, installing, and commissioning equipment, guiding customers through every project phase to achieve the best results in constructing reliable and efficient cold storage facilities.

For more information about cold storage equipment, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

In conclusion, the Bitzer reciprocating compressor, utilizing advanced technologies and precise design, holds a special position among refrigeration equipment. The Bitzer brand compressor is a reliable choice for engineers not only due to its high efficiency and long durability but also because of its dependability under various operating conditions. Full familiarity with the components of the Bitzer reciprocating compressor enables maintaining system performance at its best

]]>The Danfoss KP1 low pressure switch is a key and widely used device in refrigeration and air conditioning systems, whose main task is to control the low pressure of the refrigerant gas in the refrigeration circuit and protect the compressor’s operation. This part falls into the category of mechanical control devices, and its operation is based on pressure changes within the circuit and a mechanical response to those changes.

When the suction pressure falls below the defined range, the switch activates and cuts off the compressor’s electrical current to prevent damage. The importance of this function is undeniable in systems that operate continuously, especially in the food, pharmaceutical, and cold storage industries.

The KP1 low pressure switch is a product of Danfoss, one of the most reputable and leading global companies in manufacturing industrial and control equipment. This model’s design ensures not only precision in operation but also high durability, maintaining performance under various climatic and environmental conditions.

Its simple yet precise mechanical structure allows continuous operation without frequent maintenance. This feature has made the KP1 one of the top choices for specialists in industrial and commercial refrigeration systems.

Other important features of the Danfoss KP1 low pressure switch include full compatibility with various refrigerants, resistance to moisture, vibration, and environmental pollution, as well as a compact design and ease of installation.

Due to its engineered design and high manufacturing quality, this device usually does not require recalibration, and with one correct adjustment, it can provide stable and reliable operation for many years. This aspect is especially valuable in large projects with numerous units and backup systems.

Another important point regarding the KP1 low pressure switch is its precise adjustability. This device has pressure cut-out and cut-in adjustment screws that allow technicians to configure the device according to the exact needs of the system and environmental working conditions.

This level of control is particularly important in systems where high pressure fluctuations or energy consumption must be maintained within a precise range. In fact, a proper KP1 adjustment can be the difference between a high-efficiency system and a costly, failure-prone system.

Overall, the Danfoss KP1 low pressure switch should not be regarded merely as an auxiliary tool, but rather as a vital part of the safety and efficiency strategy in refrigeration systems. With its precise operation, high reliability, and design aligned with industrial requirements, this device is a smart choice not only technically but also economically.

With the help of this component, costly failures can be minimized, main equipment like compressors protected, and the useful life of the system significantly extended.

Features and Technical Specifications of Danfoss KP1 Low Pressure Switch Components

The Danfoss KP1 low pressure switch, as one of the most widely used low-pressure switches in refrigeration and air conditioning systems, is notable not only for its control performance but also for the precise design of its components and high build quality, which have drawn the attention of experts in this field.

Each component in this device is designed with a specific purpose, and together they coordinate perfectly to ensure safe and stable operation. The overall structure of this device offers fast response, high accuracy, and long-term durability simultaneously.

At the heart of this system lies the pressure-sensitive diaphragm. This diaphragm is usually made from stainless steel or corrosion-resistant alloys and its primary function is to detect pressure changes in the suction circuit. With increasing or decreasing pressure, the diaphragm bends, and this mechanical movement is transferred to other parts to ultimately open or close the electrical contacts. The quality and precision of this diaphragm directly affect the sensitivity and correct function of the device.

Another vital component in the KP1 structure is the pressure adjustment spring. This spring, with its restoring force, provides resistance against diaphragm movement, and its precise adjustment determines the switch’s operating pressure range.

Users can manually and accurately adjust the cut-out and cut-in pressures via the pressure adjustment screws connected to this spring. These screws are designed so that even in industrial environments subject to vibration or fluctuation, their positions do not change and the settings remain stable.

The electrical contacts in the Danfoss KP1 low pressure switch play a key role in sending the cut-off or connection command to the compressor. These contacts are made from alloys resistant to sparking, corrosion, and high temperatures.

The operation mechanism of these contacts is designed to react instantaneously and precisely in critical situations to prevent serious damage to equipment. The mechanical lever also acts as an interface between the diaphragm and the contacts, responsible for transferring movement with high accuracy.

Other important components of this device include the spring holder base, terminal protective cover, and earth connection for electrical safety. The spring base is designed to prevent the spring’s position from changing over time. The terminal protective cover, besides mechanical protection, prevents moisture, dust, and environmental damage from entering internal parts. Additionally, the earth connection ensures safety against potential leakage currents or faulty grounding.

Overall, the internal component structure of the Danfoss KP1 low pressure switch is designed based on precise engineering principles and high-quality raw materials. This combination makes the KP1 stand out not only in technical performance but also in durability, safety, and reliability. Accurate knowledge of these components is essential and very practical for technicians and engineers involved in installing, adjusting, or maintaining these devices.

Operation and Adjustment of Danfoss KP1 Low Pressure Switch

The operation of the Danfoss KP1 low pressure switch is based on simple yet precise mechanical principles. This low pressure switch is designed to continuously monitor the refrigerant gas pressure in the compressor suction line and, if this pressure drops excessively, it interrupts the electrical current to prevent the compressor from operating under dangerous conditions.

The importance of this function lies in the fact that a drop in suction pressure can indicate refrigerant leakage, blockage in the circuit, or malfunction of the compressor, which if ignored, can lead to serious damage to the refrigeration system.

Inside the KP1 low pressure switch, there is a pressure-sensitive diaphragm directly connected to the refrigeration suction circuit. When the pressure falls below the set value, the diaphragm deforms, and this change is transferred via a mechanical lever to the spring assembly and electrical contacts.

Through this mechanism, the compressor’s electrical current is cut off to prevent unsafe operation. When the pressure returns to normal levels, the diaphragm returns to its original position, allowing the circuit to reconnect.

Pressure adjustment in the Danfoss KP1 low pressure switch is done via special screws connected to internal springs. These screws are usually located on the device body, and by turning them, the cut-out and cut-in pressures can be precisely set.

The cut-out pressure is the point at which the compressor shuts off, and the cut-in pressure is the point where, after favorable conditions return, the compressor restarts. The difference between these two values, known as the “differential,” is important to prevent frequent on/off cycling of the compressor.

During adjustment, the technician must select appropriate cut-in and cut-out values based on the type of refrigerant, refrigeration system type, evaporation temperature, and operating pressure of the circuit. For example, in a cold storage system using R404A refrigerant, the suction pressure range is typically lower than in residential air conditioning systems. Incorrect selection of these values can cause system malfunction, reduced efficiency, or even compressor damage.

Another important point in adjusting this device is ensuring safety during work. Adjustment must be done when the device is powered off, and after completion, the device’s operation should be verified via pressure testing and a pressure gauge. It is also recommended that after any setting changes, the protective covers of the screws and terminals be reinstalled to prevent dust, moisture, or accidental impacts.

The precise operation and flexible adjustment capability of the Danfoss KP1 low pressure switch make it a powerful tool in managing the performance of refrigeration systems. Mastery of this adjustment method by any professional refrigeration technician not only demonstrates technical knowledge but also guarantees the long-term health and stability of the entire system.

Applications and Benefits of Using Danfoss KP1 Low Pressure Switch in Refrigeration Systems

The Danfoss KP1 low pressure switch, as a vital component in refrigeration systems, has wide applications in protecting and optimizing compressor performance. This low pressure switch, by accurately detecting refrigerant pressure drops, prevents possible compressor damage and thus extends equipment service life.

Furthermore, the use of KP1 improves system safety and reduces maintenance costs by preventing costly failures caused by improper compressor operation.

Additionally, the precise cut-in and cut-out pressure adjustability of this device enables compatibility with various systems and refrigerants, helping to increase the overall system efficiency. These features make it a reliable and efficient choice for use in cold storage facilities, chillers, and industrial air conditioning systems.

Importance of Choosing Quality Equipment like Danfoss KP1 in Building Refrigeration Systems

Selecting quality equipment such as the Danfoss KP1 low pressure switch is of utmost importance in building refrigeration systems because these components not only guarantee precise and stable system performance but also play a vital role in maintaining safety and preventing costly failures.

Using high-quality equipment increases the overall system lifespan, reduces the need for frequent repairs, and improves energy efficiency. Especially in industrial and commercial environments where refrigeration systems operate under heavy load and stress, the quality of control components like the KP1 directly affects productivity and operational costs. Therefore, investing in reputable and standard equipment is a guarantee for reliable and continuous operation of refrigeration systems.

?Why Choose Tehran Sarma Engineering Company for Selecting Refrigeration Equipment

With years of specialized experience in designing, supplying, and installing cold storage equipment, Tehran Sarma Engineering Company is considered one of the most reputable centers in the field of industrial refrigeration, capable of providing the best technical solutions and consultations for selecting the most suitable equipment.

This company, by accurately understanding customer needs and utilizing up-to-date knowledge with a specialized team, ensures that each part and device is selected according to environmental conditions, product type, and cold storage capacity to optimize energy consumption and ensure long-term, reliable system performance.

Working with Tehran Sarma means access to high-quality equipment, professional after-sales services, and continuous technical support that can minimize technical errors and unnecessary costs, ultimately increasing cold storage efficiency and lifespan.

For more information about various cold storage construction equipment, you can visit Tehran Sarma’s website or contact via phone numbers 09121906418 and 02177972256.

The Danfoss KP1 low pressure switch is recognized as one of the most widely used low pressure switches in refrigeration systems and plays a significant role in system safety and optimal performance. Its components, including diaphragm, spring, adjustment screw, and electrical contacts, all work in coordination. Reviewing the components of the Danfoss KP1 shows that this device is a reliable option for pressure control in industrial environments.

Source:

https://www.coldstorageus.com/

]]>

- Body

The main body of the Danfoss ball valve is made of steel or brass with an anti-corrosion coating to resist pressure and corrosion. The body is designed to allow refrigerant flow with minimal pressure drop. The strength of the body directly affects the overall safety and durability of the valve, especially in systems exposed to temperature fluctuations and high pressure. - Internal Ball

The ball inside, usually made of stainless steel or resistant alloys, plays the main role in opening and closing the flow path. This ball rotates 90 degrees (¼ turn) to open or close the fluid passage. Its smooth and precise surface ensures a complete seal and reduces leakage, which is very important to maintain refrigeration system efficiency. - Valve Seat

The seat is typically made from PTFE (Teflon) or similar materials that resist corrosion, temperature, and pressure. This part creates a complete seal between the ball and the body. The quality of the seat directly impacts internal leakage prevention and maintaining proper system pressure. - Handle & Rotation Mechanism

The valve handle allows the user to easily open or close the valve with a single 90-degree turn. Some models feature a rotation stop to prevent over-opening or over-closing. Additionally, some handles can be locked to increase system safety. - Burst-Proof Spindle

The spindle, which transmits motion from the handle to the ball, is designed in newer models to resist cracking and breaking. This feature prevents sudden refrigerant leaks and maintains system safety in critical conditions. - Seal Cap

The seal cap, usually made of durable plastic or PTFE, prevents moisture or contaminants from entering the valve. In some models, this cap is designed as a single piece to comply with safety standards such as EN 378. This part is very important for ensuring long-term valve performance. - Access Port

Some models include a special port for refrigerant charging or evacuation. This port allows servicing and maintenance without fully opening the system. This feature makes inspection and testing easier in Danfoss ball valves.

Each component of the Danfoss ball valve plays a specific role in ensuring the safe, effective, and stable operation of refrigeration systems. Precise design and the use of high-quality materials have made Danfoss ball valves a reliable choice in various industries. Understanding these components is essential for installers, technicians, and engineers working in refrigeration, helping extend equipment lifespan and reduce maintenance costs.

Explanation of the Role of Danfoss Ball Valve in Refrigeration Systems

The Danfoss ball valve is one of the most important control components in refrigeration and air conditioning systems, playing a fundamental role in managing refrigerant flow. These valves, manufactured with a simple yet very precise design, are responsible for opening or closing the fluid flow in refrigeration lines and are especially critical during repair, service, or system adjustment.

Ball valves are installed in different parts of the system to isolate components or paths without needing to fully evacuate the refrigerant from the entire system.

The functional structure of the Danfoss ball valve is based on a metal or alloy ball inside the valve body that opens or closes the fluid passage by rotating 90 degrees. This simple, low-friction mechanism allows fast operation with minimal leakage.

One advantage of this design is the low operating force required while still guaranteeing complete sealing of the path, which is especially important in high-pressure systems or sensitive applications.

In refrigeration systems, ball valves are usually installed at accessible points such as compressor inlet/outlet, expansion valve, filter dryer, and other key equipment. These installation points allow technicians to quickly block the refrigerant path during problems and carry out necessary operations without disrupting or damaging the entire system. This feature makes the ball valve an essential tool for system safety and reliability.

Besides flow control, many Danfoss ball valve models include an access port. These ports enable pressure measurement, gas evacuation, or refrigerant charging and play a crucial role in troubleshooting, initial startup, or periodic servicing. These additional features make the valve not just a simple valve but a multifunctional and smart component of refrigeration systems.

Technically, Danfoss ball valves are designed to perform stably against temperature fluctuations, high humidity, and varying pressures. The use of materials like brass, stainless steel, and PTFE increases valve durability and resistance to corrosion, leakage, and mechanical damage. Additionally, the burst-proof spindle design and wear- and heat-resistant seats ensure reliable long-term operation.

The Danfoss ball valve is not just a simple mechanical part for opening and closing flow paths but plays a key role in system safety, efficiency, and stable operation. Without this component, controlling and managing refrigerant flow, especially in emergencies or service times, would be very difficult and risky. Therefore, using high-quality ball valves, especially from reputable brands like Danfoss, is a fundamental principle in designing and maintaining modern refrigeration systems.

Technical Analysis of Danfoss Ball Valve Components in High-Pressure Applications

In high-pressure systems, the first critical component is the ball valve body. The body is usually made of hard brass or stainless steel and is designed to withstand high pressures without deformation or leakage.

In models specifically for high-pressure applications, the body thickness is increased and welding or joints are done with high-precision laser technology to provide maximum mechanical strength. This body structure not only withstands internal pressure but also performs stably under sudden pressure shocks.

Next, the internal ball, as the main element in opening and closing the flow path, plays a vital role. In high-pressure applications, this ball is made of alloy steel with a chrome or nickel coating to provide higher resistance to wear, pressure, and corrosion.

The smooth and precise surface of the ball ensures complete sealing without leakage during opening and closing. At high pressures, even the slightest defect on the ball’s surface can cause leakage or pressure drop in the system; therefore, the manufacturing quality of this component is critical.

The valve seat is also a key component of the Danfoss ball valve that experiences significant stress under high pressure. In Danfoss ball valves, the seat is usually made of modified PTFE, which has very high resistance to high temperature, pressure, and chemicals.

In high-pressure models, the seat is designed so that when compressed under pressure, its contact area with the ball increases, thus maintaining a complete seal even under harsh conditions. This special material also prevents irreversible deformation, a factor that plays a key role in the valve’s durability.

Considering the spindle in high-pressure design is also important. Danfoss employs a burst-proof spindle design, where the spindle is constructed to resist breaking or deformation in case of sudden pressure spikes. This design is especially vital to prevent sudden leaks or fluid discharge, as any failure in this area can lead to serious accidents or complete system shutdown.

On the other hand, the seal cap and internal washers in the Danfoss ball valve also play a complementary role in maintaining valve safety. Under high pressure, the stress on connection points is very high, and without proper sealing caps and seals, the risk of leakage increases. In Danfoss ball valves, these components are designed as integrated parts and comply with high safety standards such as EN 378 to ensure reliable operation even in critical conditions.

Another notable feature in high-pressure models is the access ports capable of withstanding high pressure. These ports, designed for charging, evacuation, or pressure measurement, are manufactured with multilayer sealing and precise threading to prevent any leakage or pressure drop during use. These features make Danfoss ball valves not only flow control tools but also precise instruments for measurement and testing.

Besides the physical components, the installation and maintenance of these valves also affect their performance under high pressure. The precise mounting holes on the body allow technicians to securely fix the valve on panels or chassis, preventing any vibration or positional change that could cause cracks or leaks.

The components of Danfoss ball valves in high-pressure models are designed to withstand harsh operating conditions including pressure, temperature, and transient fluctuations, providing stable, safe, and reliable performance. Choosing these valves for industrial applications not only reduces the risk of leakage and failure but also increases the overall lifespan of the refrigeration system.

Impact of Danfoss Ball Valve Component Quality on Refrigeration System Durability and Safety

The quality of Danfoss ball valve components plays a very important role in the durability and safety of refrigeration systems. Using high-quality, standardized ball valves ensures stable system performance and prevents sudden leaks or failures.

This not only extends equipment life but also guarantees overall system safety, preventing potential hazards such as gas leaks or pressure drops. Therefore, selecting high-quality Danfoss ball valves is a key factor for optimal efficiency and safety in refrigeration systems.

Maintenance and Repair of Danfoss Ball Valve Components: Practical Tips for Technicians

Maintenance and repair of Danfoss ball valve components are very important because these parts play a key role in controlling fluid flow in refrigeration systems, and any defect or failure can reduce system efficiency and even cause safety issues.

For technicians, familiarity with practical maintenance tips is essential; these include periodic inspection of the valve’s physical condition, regular cleaning to prevent clogging and contamination buildup, using appropriate tools for proper opening and closing, and ensuring the integrity of connections and seals.

Also, following the Danfoss manufacturer’s service and replacement guidelines helps maintain the valve’s optimal performance and extends its service life. Adhering to these tips not only prevents sudden failures but also optimizes energy consumption and reduces long-term repair costs.

Why Choose Tehran Sarma Engineering Company for Selecting the Best Parts and Options for Cold Storage Construction?

Tehran Sarma Engineering Company, as a pioneer in cold storage construction, utilizes high technical expertise, extensive experience, and premium quality parts and equipment, making it the best choice for selecting suitable components and solutions in this industry.

The company precisely identifies the needs of each project and offers specialized consulting to ensure all parts are optimally selected according to environmental conditions and expected performance. Additionally, Tehran Sarma provides continuous technical support and adheres to international standards to guarantee that constructed cold storages have unparalleled durability, energy efficiency, and safety, supporting customers to achieve the best results.

For more information about cold storage construction pricing, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

In industrial and commercial refrigeration systems, Danfoss ball valves are widely used due to their high quality and reliable performance. The role of Danfoss ball valves is to precisely control refrigerant flow and allow quick shutoff without damaging the system. Reviewing the components of Danfoss ball valves reveals their robust design, effective sealing, and easy installation—all contributing to improved overall system performance.

]]>

Bitzer oil is considered one of the most essential functional components in refrigeration compressors and plays a crucial role in maintaining stability, efficiency, and longevity of these devices. These oils are specifically designed and manufactured for compressors made by Bitzer company to be compatible with diverse operating conditions and cooling system requirements.

The proper performance of a compressor depends not only on the quality of mechanical parts and engineering design but also largely on the type and quality of oil used in it.

During the compression process of refrigerant gases, the internal parts of the compressor are subjected to high pressure and temperature and are in constant contact with each other. Under these conditions, Bitzer oil forms a lubricating film between the parts, preventing wear, friction, and excessive heat.

In addition to lubrication, the oil has other responsibilities such as cooling internal components, sealing in certain compressor areas, and reducing vibration levels. These simultaneous functions make the selection of the proper oil very important for optimizing compressor performance.

Another key role of Bitzer oil is preventing the formation of deposits and contamination within the compressor circuit. If an unsuitable oil is chosen or the oil quality degrades due to prolonged use, suspended particles or unwanted chemical compounds may form in the system, causing damage to valves, bearings, and other sensitive compressor parts.

High-quality Bitzer oil, with stable and oxidation-resistant compounds, prevents such damages and provides more uniform operating conditions for the device.

It should be noted that Bitzer oil is not considered just a simple lubricant but a technical element with multifunctional performance. Using the appropriate oil, proper maintenance, and continuous monitoring of oil condition in the system directly impact the performance of the entire refrigeration system. For this reason, the selection and careful review of Bitzer oil is a fundamental and indispensable step in the design, operation, and maintenance of refrigeration compressors.

Introduction to Different Categories of Bitzer Oils

Bitzer oil is produced and supplied in various categories depending on the type of application and operating conditions, each having unique features, compositions, and capabilities. These categories are based on the oil base type and compatibility with different refrigerants. Bitzer company, with a precise understanding of refrigeration and air conditioning industry needs, has developed various types of oil compatible with common refrigerant gases and diverse operating conditions.

One of the most common categories of Bitzer oils is mineral oils, which are usually used in compressors with traditional refrigerants such as R22. These oils are petroleum-based and perform adequately in systems with normal pressure and temperature. However, with the increased use of new and environmentally friendly refrigerants, mineral oils have gradually been replaced by more advanced oils.

In response to new demands, Bitzer has also developed polyester or POE oils. This type of oil is highly suitable for use with HFC refrigerants such as R134a, R404A, and R407C. Polyester oils, due to their high chemical stability and better miscibility with modern refrigerants, are the primary choice in many current cooling systems. Nevertheless, because these oils are more sensitive to moisture and contamination, extra care should be taken in their storage and handling.

Another group of Bitzer oils is known as alkylbenzene-based oils. These oils perform between mineral and polyester oils and are usually used in systems with HCFC refrigerants and some hydrocarbons. They have good resistance to thermal decomposition and are chemically more stable than mineral oils.

Considering the high diversity of refrigerants and continuous changes in environmental standards, Bitzer oil classification not only indicates the type of lubricant but also reflects a precise technical approach to meet the needs of modern refrigeration systems. Proper knowledge of these categories helps technicians and engineers confidently select compatible and suitable oils for each system and ensure safe and stable operation.

Selecting the Appropriate Bitzer Oil Based on Refrigerant Type and Compressor

Selecting the proper Bitzer oil according to the type of refrigerant and compressor is one of the most important technical decisions in the design, installation, and maintenance of refrigeration and air conditioning systems. This choice directly affects compressor performance, efficiency, and lifespan, and neglecting it may cause serious damage to the system.

Oil not only lubricates moving parts but also plays roles such as cooling, sealing, and carrying suspended particles in the system. Therefore, precise compatibility between the type of oil, refrigerant, and compressor is a vital principle for safe and stable system performance.

The first factor to consider when selecting Bitzer oil is the refrigerant type used in the system. Refrigerants, depending on their chemical structure, have different mixing and compatibility capabilities with oil. For example, older chlorinated refrigerants like R22 are well compatible with mineral oils and have been widely used in cooling systems in the past.

In contrast, newer refrigerants such as R134a, R404A, and R410A, which belong to the HFC category, are incompatible with mineral oils and require the use of polyester (POE) oils for proper performance. POE oils have higher polarity and better solvency for these refrigerants, thus circulating well in the system and preventing liquid refrigerant return to the compressor.

Another important point is the type of compressor used in the system. Different compressors—such as reciprocating, screw, and scroll compressors—have different designs and operational requirements. Reciprocating compressors have more internal components that create frequent mechanical contacts; therefore, using oil with suitable viscosity and high lubricating properties is especially important for them.

In contrast, screw compressors, which are usually used in high-capacity industrial systems, operate at higher temperatures and pressures and require oils with thermal stability and oxidation resistance. The oils designed by Bitzer for this type of compressor not only provide optimal lubrication but also have the capability to continuously cool moving parts.

It is also necessary to pay attention to environmental operating conditions. In systems operating in humid areas or with large temperature fluctuations, the likelihood of moisture entering the system increases. POE oils, due to their high moisture absorption property, should be used with caution and under strict maintenance protocols in such conditions. The presence of moisture in the oil can cause its chemical breakdown, increase acidity, and ultimately damage compressor components. Therefore, packaging, storage, and even the method of oil replacement in these systems require greater care.

In some special cases, natural refrigerants like ammonia or CO₂ may be used in refrigeration systems. In these cases, Bitzer has designed specific oils compatible with the chemical properties of these refrigerants. For example, alkylbenzene-based or polyalphaolefin oils are recommended in some of these applications. These oils have better antioxidant properties and exhibit greater resistance under high pressure.

Considering all these points, it can be said that selecting the appropriate Bitzer oil for a cooling or air conditioning system is not merely a simple choice among several options, but requires a precise understanding of the technical characteristics of the refrigerant, compressor type, operating conditions, and system performance requirements.

Consulting the compressor manual, reviewing Bitzer’s technical recommendations, and considering the practical experience of installers and technicians are among the approaches that can guide this process. A precise and intelligent oil selection not only guarantees system performance but also prevents complex future problems and minimizes maintenance and repair costs.

Reviewing Characteristics such as Viscosity, Pour Point, Thermal and Chemical Stability in Bitzer Oil

The technical properties of Bitzer oil play a very important role in ensuring optimal performance and durability of refrigeration compressors. Among these properties is viscosity, which determines the oil’s resistance to flow and must be chosen so that proper lubrication is provided at different temperatures. The pour point is another critical parameter indicating the lowest temperature at which the oil can still flow, which becomes especially important for refrigeration systems operating in cold environments.

Thermal stability refers to the oil’s ability to resist decomposition and chemical changes caused by high temperatures, allowing the oil to continue performing its functions under harsh operating conditions without quality loss. Additionally, the chemical stability of Bitzer oil ensures that the oil’s compounds do not react destructively over time with the refrigerant or system internals, preventing the formation of deposits and contamination. This combination of features ultimately helps maintain the long-term health and efficiency of the compressor.

Maintenance, Replacement, and Common Problems in Using Bitzer Oil

Proper maintenance of Bitzer oil plays a crucial role in preserving efficiency and extending the life of refrigeration compressors. Attention to points such as periodic oil quality checks, prevention of contamination by foreign particles and moisture, and adherence to oil replacement schedules are fundamental principles. Contaminated or oxidized oils can cause filter clogging, reduce lubricating properties, and increase internal compressor friction, gradually leading to performance degradation and even component failure.

Common problems in using Bitzer oil include viscosity reduction, acidity increase, and deposit formation, which are usually the result of improper maintenance or long-term operation without timely oil replacement. Also, following the manufacturer’s technical guidelines, including using proper equipment and methods for oil draining and replacement, is especially important to preserve oil quality and ensure the refrigeration system always operates under optimal conditions.

Using the Best Compressor Oils with the Help of Tehran Sarma Engineering Company

Tehran Sarma Engineering Company, relying on its experience and expertise in refrigeration equipment, plays an important role in supplying and distributing the best Bitzer compressor oils. This company assists customers in selecting high-quality and suitable oils through precise technical consulting and identifying each system’s specific needs to ensure optimal performance and longer compressor life.

Additionally, Tehran Sarma ensures that the oils supplied comply with the latest technical and environmental standards by closely cooperating with reputable manufacturers and having access to genuine and standard products. Using these premium oils and benefiting from the specialized services of Tehran Sarma Engineering Company is a reliable step toward increasing efficiency and reducing maintenance costs of refrigeration systems.

For more information about cold storage construction prices, you can visit Tehran Sarma’s website or contact via phone numbers 09121906418 and 02177972256.

Bitzer oil is designed for the optimal performance of compressors manufactured by Bitzer and plays a key role in maintaining efficiency and increasing the device’s lifespan. Bitzer oils are available in various models such as BSE32, BSE55, and B100 for use with different refrigerants. Bitzer oil and its types are selected based on the compressor type and operating conditions to prevent wear and damage to parts.

]]>

- What kind of systems are refrigeration systems?

Refrigeration systems refer to a set of equipment and processes designed to lower temperature and maintain the necessary cooling in different environments. The primary operation of these systems is based on the principles of heat transfer; meaning the heat present in one area is removed and transferred to another area to cool the desired environment.

Contrary to common belief, the refrigeration process is not about producing cold, but rather removing heat from the environment, which results in cooler conditions. This principle is common in all refrigeration systems regardless of their type or structure.

In a typical refrigeration system, main components such as the compressor, condenser, evaporator, and expansion valve work together to form the cooling cycle. The compressor compresses the refrigerant gas and sends it to the condenser, where it loses heat and turns into a liquid. Then this liquid passes through the expansion valve to the evaporator, where its pressure drops, causing it to evaporate and absorb heat from the environment. - Important components in refrigeration units

Structurally, there are various types of refrigeration systems, each designed for specific needs. The most common type is the vapor compression system, widely used in refrigerators, air conditioners, and cold storage rooms.

In contrast, absorption systems work without a compressor and use heat energy to perform the refrigeration process; this type is more suitable for locations with limited electricity access. Also, thermoelectric systems based on the Peltier effect are used in small electronic devices such as car refrigerators.

Moreover, freon and ammonia refrigeration systems are used industrially depending on the need. Freon systems are mostly applied in residential and commercial settings and commonly use synthetic refrigerants, while ammonia systems are favored in larger industries like petrochemical plants and industrial cold storage due to their high cooling capacity and efficiency.

Heat pumps are a special type of refrigeration system that can provide both cooling and heating simultaneously and are widely used in modern buildings. - Refrigeration systems and their applications

The applications of refrigeration systems in everyday life and industry are extensive. From the simplest use in household refrigerators to massive cold storage facilities, all depend on refrigeration technologies. In the food industry, refrigeration is used to prevent spoilage of raw materials and preserve products.

In pharmaceuticals, some medicines must be stored at specific temperatures, which is impossible without refrigeration systems. In fields such as air conditioning, petrochemicals, space technology, and even automobiles, refrigeration systems play a key role.

A proper understanding of refrigeration system fundamentals and applications is not only essential for engineers and technicians in HVAC and cooling fields but also helps anyone working in related industries to select optimal equipment and improve efficiency.

With technological advancements, the future of refrigeration systems is moving toward the use of environmentally friendly refrigerants and reduced energy consumption, which highlights the increasing importance of these systems in energy management and environmental preservation.

Types of Refrigeration Systems and Explanation of How Each Works

- Vapor Compression Refrigeration System

This system is one of the most common and widely used refrigeration methods worldwide. Its operation is based on the vapor compression refrigeration cycle, which includes four main components: compressor, condenser, expansion valve, and evaporator.

- Compressor: Responsible for increasing the pressure and temperature of the refrigerant. Low-pressure vapor refrigerant enters the compressor, where it is compressed into a high-pressure, high-temperature vapor.

- Condenser: The hot, high-pressure refrigerant vapor enters the condenser and transfers its heat to the surroundings (usually air or water), turning into a high-pressure liquid.

- Expansion valve: The high-pressure liquid refrigerant passes through this valve, reducing its pressure and temperature, preparing it to evaporate in the evaporator.

- Evaporator: The low-pressure refrigerant liquid evaporates in the evaporator, absorbing heat from the environment and cooling it. The refrigerant vapor then returns to the compressor, and the cycle repeats.

Due to its high efficiency, precise temperature control, and ease of use, this system is a primary refrigeration method.

- Absorption Refrigeration System

The absorption refrigeration system is an important alternative to the compression system, using thermal energy instead of a mechanical compressor to generate the refrigeration cycle. This system is very economical when thermal energy is cheap and available.

- Refrigerant and absorber: Typically, ammonia is used as the refrigerant and water as the absorber. The refrigerant evaporates in the evaporator and absorbs heat from the environment.

- Absorption: The refrigerant vapor is absorbed by the absorber solution, forming a low-pressure mixture.

- Generator: Applying heat to the solution separates the refrigerant from the absorber, releasing hot refrigerant vapor.

- Condenser and expansion valve: Similar to the compression system, the refrigerant vapor moves to the condenser and turns to liquid, then its pressure drops and returns to the evaporator.

The main advantages are mechanical simplicity, reduced electricity consumption, and the ability to use diverse heat sources. Disadvantages include larger equipment size and lower efficiency compared to compression systems.

- Thermoelectric Refrigeration System

This system works based on the Peltier effect, a phenomenon where electric current passing through the junction of two semiconductors causes a temperature difference.

- Operation: When electric current flows through a thermoelectric module, one side becomes cold, and the other side becomes hot. By placing the cold side on the target environment, cooling occurs, while heat is conducted away from the hot side and dissipated.

- Advantages: No moving parts, silent operation, compact size, and precise temperature control.

- Disadvantages: Low efficiency and limited cooling capacity, making it suitable for small and specialized applications.

This type is mostly used in medical, electronics, and portable devices.

- Evaporative Cooling System

The evaporative cooling system is one of the simplest and oldest methods for reducing temperature, based on water evaporation. In this process, air passes through a wet surface.

- Mechanism: During evaporation, latent heat is absorbed from the air, reducing the air temperature. The air exits the wet section cooler but with higher humidity.

- Applications: Very effective in dry and hot climates, used in simple air conditioning systems, swamp coolers, and some industrial processes.

Limitations: Less effective in humid areas because the exiting air approaches saturation and evaporation decreases.

Due to its low energy consumption and lower construction and maintenance costs, this system is often the most economical choice.

What are the main components of refrigeration systems?

Refrigeration systems consist of a set of main components, each playing a vital role in the overall operation of the device. These components work precisely and harmoniously to enable the heat transfer process and temperature reduction, ensuring the desired environment reaches the target temperature. Each part of the system, with its specific features and functions, forms a part of the refrigeration cycle, and without any one of them, the system’s operation is disrupted.

One of the essential components of refrigeration systems is the compressor, which is considered the heart of the system. This part is responsible for compressing the refrigerant and increasing its pressure and temperature. With the increased pressure, the refrigerant can effectively dissipate heat in the subsequent sections of the system. The compressor converts mechanical energy into thermal energy and pressure, thus driving the refrigeration cycle.

Another important component in refrigeration systems is the condenser, which is responsible for dissipating heat from the refrigerant. After compression and temperature increase, the refrigerant enters the condenser, where it transfers its heat to the surrounding environment. This heat transfer causes the refrigerant to change from a gas to a liquid, preparing it for the continuation of the cycle. The condenser is usually in contact with ambient air or water to dissipate heat as efficiently as possible.

The expansion valve is also a vital component that suddenly reduces the pressure of the refrigerant, causing its temperature to drop and preparing it to absorb heat in the next stage. This pressure drop plays an important role in creating the necessary temperature difference for heat transfer. The expansion valve is designed to control the flow of refrigerant and balance the pressure between different parts of the system.

The evaporator is another part of refrigeration systems where the liquid refrigerant evaporates and absorbs heat from the environment. This heat absorption cools the desired space. The evaporator is typically in direct contact with the environment or the system’s internal air and is the main part responsible for cooling. The performance quality of this component directly affects the overall efficiency of the system.

Together, these components form a continuous cycle that works persistently to reduce the environmental temperature. Also, the presence of proper piping and connections, compressor lubrication, and control and safety devices contribute to the correct and stable operation of the system. Each of these components, carefully engineered and designed, ensures that the refrigeration system operates effectively and reliably under various conditions.

Industrial and Domestic Applications of Refrigeration Systems

Refrigeration systems play a very important role in everyday life and industry, with wide-ranging applications. In domestic environments, these systems are mainly used for food storage in refrigerators and freezers, air conditioning, and cooling residential spaces.

In various industries, refrigeration systems play a vital role in preserving quality and extending product life; for example, in the food industry for storing and freezing products, in pharmaceuticals for maintaining storage conditions for medicines and vaccines, in the oil and petrochemical industries for cooling equipment and processes, and also in data centers to manage server temperatures and prevent overheating.

Overall, refrigeration systems provide precise temperature control, increase productivity, reduce material wastage, and maintain product health, playing an indispensable role in improving human life quality and industrial performance.

Maintenance, Problems, and Optimization of Refrigeration Systems and Ways to Increase Efficiency

Proper maintenance of refrigeration systems is of high importance because the stable performance and lifespan of these devices directly depend on the health of their components. Common problems such as refrigerant leaks, compressor failure, clogged filters, and reduced condenser efficiency can decrease performance and increase energy consumption.

To prevent these issues, periodic inspections, cleaning and replacement of worn parts, refrigerant pressure and temperature control, and system performance checks are recommended. Optimizing refrigeration systems using modern technologies—such as employing environmentally friendly refrigerants, installing smart controllers, and optimizing refrigerant flow paths—can significantly increase energy efficiency.

Proper Design of Refrigeration Systems and the Role of Tehran Sarma Engineering Company in this Field

Proper design of refrigeration systems plays a very important role in ensuring optimal performance, increasing energy efficiency, and reducing operational costs. This is because accurate component selection, determining appropriate capacity, and coordination between different system parts are key factors in achieving an efficient and stable refrigeration cycle.

In this regard, Tehran Sarma Engineering Company, utilizing technical expertise and extensive experience in the design and implementation of refrigeration systems, has been able to offer comprehensive and customized solutions that, besides fully meeting customer needs, guarantee high quality and durability while adhering to international standards.

Using advanced design software and a specialized team, this company is capable of executing projects of varying complexity in the best possible way and plays an important role in the development and improvement of refrigeration infrastructure in various industries.

For more information about cold storage construction prices, you can visit the Tehran Sarma website and contact us at 09121906418 and 02177972256.

Refrigeration systems are designed to create and maintain low temperatures in various environments and play a vital role in industrial and domestic processes. Refrigeration units, as the operational parts of these systems, perform the cooling operation. Accurate understanding of refrigeration systems and their applications can lead to optimized energy consumption and increased efficiency across various industries.

Source:

https://www.coldstorageus.com/

]]>

The structure of an electronic expansion valve typically includes a stepper motor, copper coils, a permanent magnet, a needle, a seat, and the valve body. These components work in coordination to ensure accurate and responsive operation.

The Electronic Expansion Valve (EEV) is an advanced component in refrigeration and air conditioning systems, tasked with precisely and intelligently regulating the amount of refrigerant entering the evaporator.

Unlike mechanical expansion valves, the electronic type continuously adjusts the valve opening based on signals from the central controller and sensors, keeping the superheat temperature at an optimal level. This accuracy in performance leads to improved efficiency, reduced energy consumption, and extended system life.

The structure of an EEV consists of several main components, each playing an essential role in the device’s precise and coordinated function. One of the key elements is the stepper motor, which performs incremental and accurate rotation. This motor operates based on electrical pulses received from the controller and adjusts the valve’s central shaft.

Inside the stepper motor are copper coils that generate a magnetic field, causing the permanent magnet to move. This movement is directly transferred to the shaft, which is connected to a thread. The thread converts rotational motion into linear motion so that lower parts of the valve, like the needle, move up or down.

The needle is one of the valve’s sensitive components and regulates refrigerant flow through its movement. This needle rests on the seat, which creates a precise surface for completely shutting off the refrigerant flow when necessary. The valve body houses all these components and provides the mechanical strength required for reliable and stable operation.

In addition to the mechanical parts, the control and electronic sections are also of great importance. Control commands from the central controller—usually based on data from temperature and pressure sensors—are sent to the stepper motor. This real-time control allows the EEV to automatically adapt to changing system conditions.

The structure of the electronic expansion valve is a combination of precise mechanical parts and an intelligent control system. This combination has made such valves widely used in advanced industrial refrigeration and modern HVAC systems. Their complex design and precise performance play a critical role in optimizing energy consumption and maintaining system performance quality.

How Does an Electronic Expansion Valve Work?

The electronic expansion valve is considered one of the key and advanced components in modern refrigeration and air conditioning systems. Its main function is to precisely regulate the refrigerant flow into the evaporator.

Unlike thermostatic or mechanical expansion valves that operate based on pressure differences or the expansion of sensitive fluids, the electronic expansion valve functions by receiving electrical commands and analyzing real-time data from the system. This feature gives the valve much higher accuracy and responsiveness in controlling the cooling process.

The operation process of the EEV starts with collecting data such as the evaporator’s inlet and outlet temperatures, compressor suction pressure, and superheat level. These values are measured by sensors and sent to a central controller—typically a digital controller or a PLC. The controller analyzes the data, calculates the optimal refrigerant flow rate, and issues the command to open or close the valve.

At the heart of the EEV’s structure is the stepper motor, which precisely adjusts the needle’s position. The stepper motor rotates in small, accurate steps upon receiving electrical pulses from the controller. This rotation is converted into linear motion via threads, causing the needle to move up or down. The needle, in a specific position on the seat, opens or restricts the refrigerant path with its movement.

Another crucial component of this structure is the copper coils within the stepper motor, which generate a magnetic field when electric current passes through. This field moves the permanent magnet and enables the motor’s precise rotation. Along with other parts like the shaft, thread, and valve body, this creates a reliable and accurate mechanical assembly.

One of the key advantages of this valve is its ability to continuously and instantly adjust refrigerant flow. This feature is particularly beneficial when the system’s thermal load is constantly changing—such as in HVAC systems for office or commercial buildings. Moreover, precise superheat control prevents liquid refrigerant from entering the compressor, protecting it from potential damage.

In addition, the EEV can communicate with advanced control systems such as BMS (Building Management Systems) or IoT platforms. This allows for remote monitoring and control, which is very effective for preventive maintenance.

The electronic expansion valve is a prime example of technological advancement in the refrigeration industry. By leveraging precise electronic and mechanical systems, it boosts system efficiency, reduces energy consumption, and extends equipment lifespan. As a result, this type of valve is widely used in industrial applications, cold storage rooms, central air conditioning systems, chillers, and even commercial refrigerators.

How Components Coordinate in an Electronic Expansion Valve

Sensors: Collecting Critical Data

In the first stage, sensors are responsible for collecting vital information from the refrigeration system. These sensors are usually installed at various points in the system, such as the evaporator inlet and outlet. Pressure and temperature sensors, in particular, are among the main tools that help determine the precise status of the system. These sensors continuously measure data such as refrigerant pressure and temperature and send this information to the control unit.

Data Processing by the Control Unit

The electronic control unit, which usually includes a microcontroller, is responsible for processing the data received from the sensors. After receiving this data, the control unit makes the necessary decisions to maintain optimal system conditions. It typically uses advanced algorithms to analyze the data and determine whether the refrigerant flow should be increased or decreased. The goal of this process is to ensure optimal system performance and prevent any disruption in the refrigeration cycle.

Actuator: Sending Commands to the Valve

After processing the information and making the necessary decisions, the control unit sends signals to the actuator of the electronic expansion valve. These signals are usually transmitted as voltage or electrical current to the valve actuator. The actuator, which is typically a stepper motor, receives the command to open or close the valve. These changes in valve position affect the refrigerant flow, allowing it to enter the evaporator precisely.

Precise Refrigerant Flow Regulation by the Expansion Valve

As the final step, the electronic expansion valve adjusts its opening based on the instructions from the actuator. These adjustments, typically carried out with high precision, set the refrigerant flow to the desired level. One of the key advantages of these valves over mechanical types is their ability to regulate refrigerant flow more accurately, enabling the refrigeration system to operate more efficiently and with lower energy consumption. This precision over time ensures the system operates in a consistently optimized state.

Continuous Monitoring and Re-adjustment

One of the main features of electronic expansion valves is their ability to continuously monitor system conditions. Sensors constantly send data on the system’s status, and in the event of changing conditions, new data is transferred to the control unit. As a result, the system can automatically make new adjustments and regulate refrigerant flow according to the updated conditions. This automatic monitoring and re-adjustment process ensures that the refrigeration system always operates under optimal conditions.

The coordination between the sensors, control unit, actuator, and electronic expansion valve allows these systems to operate with high accuracy and efficiency. The use of electronic expansion valves in refrigeration and air conditioning systems improves performance, extends equipment life, and reduces energy consumption. These advanced technologies enable refrigeration systems to respond automatically and optimally to changing loads and environmental conditions, maintaining consistent performance over time.

Tips for Maintaining Electronic Expansion Valves and Preventing Potential Failures

To properly maintain an electronic expansion valve and prevent potential failures, it is essential to regularly inspect the system for cleanliness and functionality. First, the sensors and connections should be thoroughly checked to ensure there is no dust or contamination that could disrupt system performance.

Additionally, refrigerant pressure and temperature should be regularly monitored to ensure the expansion valve is operating correctly. If the valve becomes blocked or malfunctions for any reason, it should be repaired or replaced immediately. Using electrical protection systems to guard against voltage fluctuations and damage to electronic circuits can also prevent serious failures. Regular maintenance and cleaning of various system components help maintain efficiency and extend the service life of the expansion valve.

The Role of Electronic Expansion Valves in Superheat Control in Refrigeration Systems

Electronic expansion valves play a critical role in controlling superheat in refrigeration systems—this refers to the temperature of the refrigerant after heat exchange in the evaporator, which is higher than its saturation temperature. By precisely regulating refrigerant flow, the valve automatically controls superheat and prevents liquid refrigerant from entering the compressor.

Accurate superheat control improves system performance, prevents compressor damage, increases energy efficiency, and helps avoid issues related to excessive or insufficient system pressure. To achieve this, the electronic expansion valve receives real-time data from sensors and sends signals to adjust refrigerant flow, keeping superheat within the desired range. This process extends system lifespan and reduces energy consumption.

The Importance of Choosing the Right Cold Storage Components such as Electronic Expansion Valves with Tehran Sarma Engineering Company

Choosing the right cold storage components, including electronic expansion valves, is crucial for optimal performance and extended service life of the refrigeration system. Tehran Sarma Engineering Company, with its wide range of products and services in the field of cold storage design and equipment supply, plays a vital role in ensuring the efficiency and productivity of refrigeration systems.

The company selects and installs suitable components according to the specific needs of each project to prevent temperature and pressure fluctuations and maintain optimal refrigeration system performance.

By partnering with Tehran Sarma, customers benefit from expert consultation, precise installation and maintenance services, and ongoing support—ensuring their cold storage systems operate to the highest standards with minimal operational costs.

For more information about cold storage construction prices, visit the Tehran Sarma website or contact them at 09121906418 and 02177972256.

Electronic expansion valves are used in cooling systems to regulate the amount of refrigerant entering the evaporator. Using electrical commands, these valves control the refrigerant flow path in real time. The structure of an electronic expansion valve includes components such as a stepper motor, shaft, needle, seat, and main body—all designed with high precision for optimal performance.

Source:

https://www.coldstorageus.com/

https://unitedinsulated.com/

]]>