سردخانه

سردخانه

- برندها

- دانفوس

- ای بی ام (EBM)

- رزنبرگ (ROSENBERG)

- ول بریز (WELL-BRAZE)

- دبلیو تی کی (WTK)

- کلیون (KELVION)

- ال آر (LR)

- زیلابگ (ZIEHL-ABEGG)

- مهر پارسه ( HMP )

- جی وی ان (GVN)

- ویکا (WIKA)

- اولب (OLAB)

- ای سی ای (ECA)

- سانهوا (SANHUA)

- دنالاین (DENALINE)

- کلدفلکس (COLD-FLEX)

- آوا (AWA)

- دیکسل (DIXELL)

- ال جی (LG)

- بیتزر

- کولترون

- تکامسه

- GMC

- CARRIER

- آرشه کار

- مولر

- کستل

- هانگسن

- کرل

- فراسکلد

- کوپلند

- پکلس

- کولمیت (CULMIT)

- گالف (GULF)

- سانیسو (SUNISO)

- تجهیزات سردخانه

- قیمت سردخانه

- ساخت سوله سردخانه

- تونل انجماد

- پیش سردکن

- برندها

- سیستم های تهویه مطبوع

- سیستم های کنترلی اتوماسیون

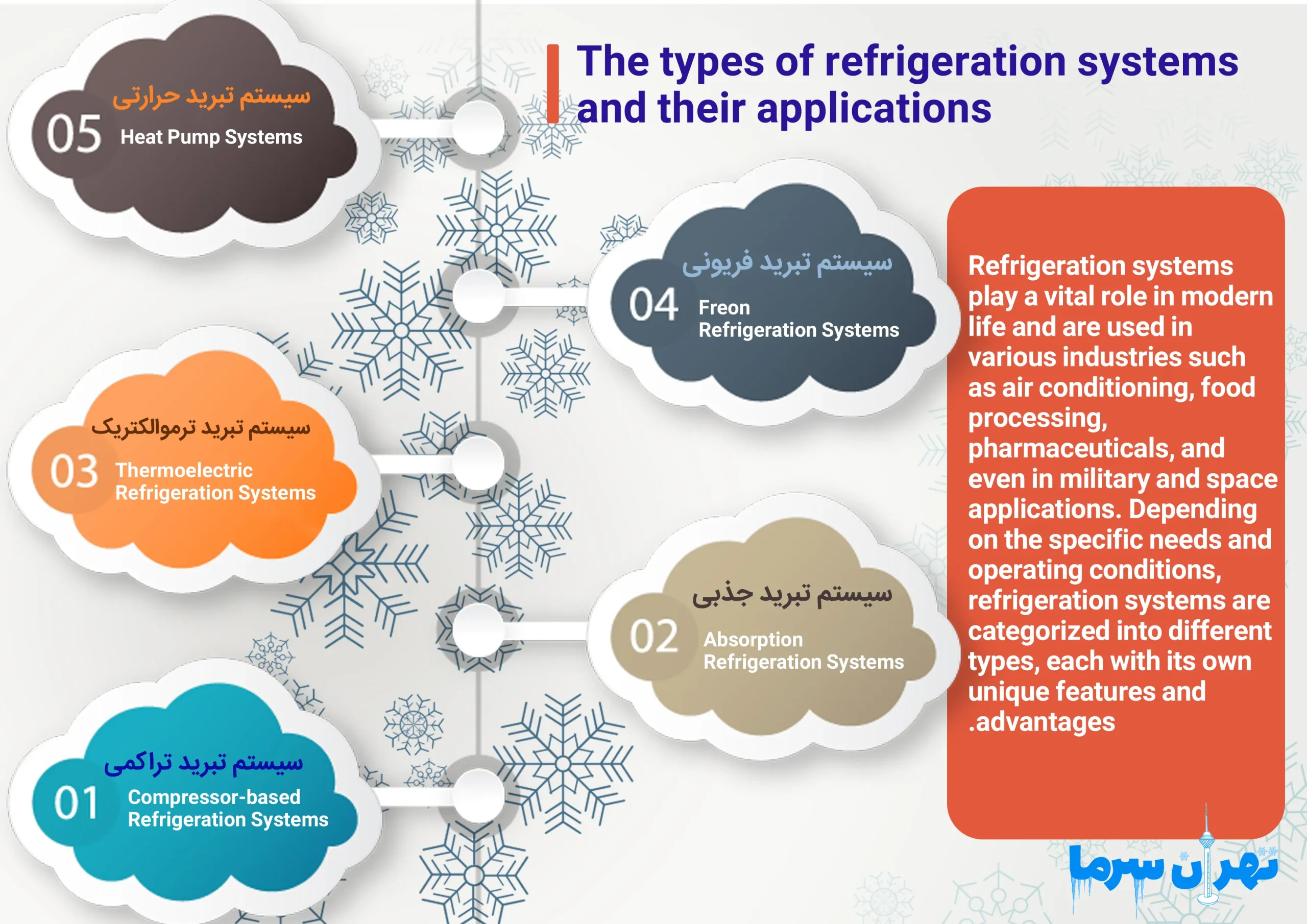

Fundamentals of Refrigeration Systems and Their Applications

Refrigeration systems are key components in various industries such as food, pharmaceuticals, and air conditioning. Their main function is to maintain the desired temperature and prevent spoilage or damage to products. Refrigeration units are manufactured in different sizes and capacities depending on their applications. Familiarity with refrigeration systems and their applications helps engineers and technicians choose the most suitable solution for each project or operational environment.

- What kind of systems are refrigeration systems?

Refrigeration systems refer to a set of equipment and processes designed to lower temperature and maintain the necessary cooling in different environments. The primary operation of these systems is based on the principles of heat transfer; meaning the heat present in one area is removed and transferred to another area to cool the desired environment.

Contrary to common belief, the refrigeration process is not about producing cold, but rather removing heat from the environment, which results in cooler conditions. This principle is common in all refrigeration systems regardless of their type or structure.

In a typical refrigeration system, main components such as the compressor, condenser, evaporator, and expansion valve work together to form the cooling cycle. The compressor compresses the refrigerant gas and sends it to the condenser, where it loses heat and turns into a liquid. Then this liquid passes through the expansion valve to the evaporator, where its pressure drops, causing it to evaporate and absorb heat from the environment. - Important components in refrigeration units

Structurally, there are various types of refrigeration systems, each designed for specific needs. The most common type is the vapor compression system, widely used in refrigerators, air conditioners, and cold storage rooms.

In contrast, absorption systems work without a compressor and use heat energy to perform the refrigeration process; this type is more suitable for locations with limited electricity access. Also, thermoelectric systems based on the Peltier effect are used in small electronic devices such as car refrigerators.

Moreover, freon and ammonia refrigeration systems are used industrially depending on the need. Freon systems are mostly applied in residential and commercial settings and commonly use synthetic refrigerants, while ammonia systems are favored in larger industries like petrochemical plants and industrial cold storage due to their high cooling capacity and efficiency.

Heat pumps are a special type of refrigeration system that can provide both cooling and heating simultaneously and are widely used in modern buildings. - Refrigeration systems and their applications

The applications of refrigeration systems in everyday life and industry are extensive. From the simplest use in household refrigerators to massive cold storage facilities, all depend on refrigeration technologies. In the food industry, refrigeration is used to prevent spoilage of raw materials and preserve products.

In pharmaceuticals, some medicines must be stored at specific temperatures, which is impossible without refrigeration systems. In fields such as air conditioning, petrochemicals, space technology, and even automobiles, refrigeration systems play a key role.

A proper understanding of refrigeration system fundamentals and applications is not only essential for engineers and technicians in HVAC and cooling fields but also helps anyone working in related industries to select optimal equipment and improve efficiency.

With technological advancements, the future of refrigeration systems is moving toward the use of environmentally friendly refrigerants and reduced energy consumption, which highlights the increasing importance of these systems in energy management and environmental preservation.

Types of Refrigeration Systems and Explanation of How Each Works

- Vapor Compression Refrigeration System

This system is one of the most common and widely used refrigeration methods worldwide. Its operation is based on the vapor compression refrigeration cycle, which includes four main components: compressor, condenser, expansion valve, and evaporator.

- Compressor: Responsible for increasing the pressure and temperature of the refrigerant. Low-pressure vapor refrigerant enters the compressor, where it is compressed into a high-pressure, high-temperature vapor.

- Condenser: The hot, high-pressure refrigerant vapor enters the condenser and transfers its heat to the surroundings (usually air or water), turning into a high-pressure liquid.

- Expansion valve: The high-pressure liquid refrigerant passes through this valve, reducing its pressure and temperature, preparing it to evaporate in the evaporator.

- Evaporator: The low-pressure refrigerant liquid evaporates in the evaporator, absorbing heat from the environment and cooling it. The refrigerant vapor then returns to the compressor, and the cycle repeats.

Due to its high efficiency, precise temperature control, and ease of use, this system is a primary refrigeration method.

- Absorption Refrigeration System

The absorption refrigeration system is an important alternative to the compression system, using thermal energy instead of a mechanical compressor to generate the refrigeration cycle. This system is very economical when thermal energy is cheap and available.

- Refrigerant and absorber: Typically, ammonia is used as the refrigerant and water as the absorber. The refrigerant evaporates in the evaporator and absorbs heat from the environment.

- Absorption: The refrigerant vapor is absorbed by the absorber solution, forming a low-pressure mixture.

- Generator: Applying heat to the solution separates the refrigerant from the absorber, releasing hot refrigerant vapor.

- Condenser and expansion valve: Similar to the compression system, the refrigerant vapor moves to the condenser and turns to liquid, then its pressure drops and returns to the evaporator.

The main advantages are mechanical simplicity, reduced electricity consumption, and the ability to use diverse heat sources. Disadvantages include larger equipment size and lower efficiency compared to compression systems.

- Thermoelectric Refrigeration System

This system works based on the Peltier effect, a phenomenon where electric current passing through the junction of two semiconductors causes a temperature difference.

- Operation: When electric current flows through a thermoelectric module, one side becomes cold, and the other side becomes hot. By placing the cold side on the target environment, cooling occurs, while heat is conducted away from the hot side and dissipated.

- Advantages: No moving parts, silent operation, compact size, and precise temperature control.

- Disadvantages: Low efficiency and limited cooling capacity, making it suitable for small and specialized applications.

This type is mostly used in medical, electronics, and portable devices.

- Evaporative Cooling System

The evaporative cooling system is one of the simplest and oldest methods for reducing temperature, based on water evaporation. In this process, air passes through a wet surface.

- Mechanism: During evaporation, latent heat is absorbed from the air, reducing the air temperature. The air exits the wet section cooler but with higher humidity.

- Applications: Very effective in dry and hot climates, used in simple air conditioning systems, swamp coolers, and some industrial processes.

Limitations: Less effective in humid areas because the exiting air approaches saturation and evaporation decreases.

Due to its low energy consumption and lower construction and maintenance costs, this system is often the most economical choice.

What are the main components of refrigeration systems?

Refrigeration systems consist of a set of main components, each playing a vital role in the overall operation of the device. These components work precisely and harmoniously to enable the heat transfer process and temperature reduction, ensuring the desired environment reaches the target temperature. Each part of the system, with its specific features and functions, forms a part of the refrigeration cycle, and without any one of them, the system’s operation is disrupted.

One of the essential components of refrigeration systems is the compressor, which is considered the heart of the system. This part is responsible for compressing the refrigerant and increasing its pressure and temperature. With the increased pressure, the refrigerant can effectively dissipate heat in the subsequent sections of the system. The compressor converts mechanical energy into thermal energy and pressure, thus driving the refrigeration cycle.

Another important component in refrigeration systems is the condenser, which is responsible for dissipating heat from the refrigerant. After compression and temperature increase, the refrigerant enters the condenser, where it transfers its heat to the surrounding environment. This heat transfer causes the refrigerant to change from a gas to a liquid, preparing it for the continuation of the cycle. The condenser is usually in contact with ambient air or water to dissipate heat as efficiently as possible.

The expansion valve is also a vital component that suddenly reduces the pressure of the refrigerant, causing its temperature to drop and preparing it to absorb heat in the next stage. This pressure drop plays an important role in creating the necessary temperature difference for heat transfer. The expansion valve is designed to control the flow of refrigerant and balance the pressure between different parts of the system.

The evaporator is another part of refrigeration systems where the liquid refrigerant evaporates and absorbs heat from the environment. This heat absorption cools the desired space. The evaporator is typically in direct contact with the environment or the system’s internal air and is the main part responsible for cooling. The performance quality of this component directly affects the overall efficiency of the system.

Together, these components form a continuous cycle that works persistently to reduce the environmental temperature. Also, the presence of proper piping and connections, compressor lubrication, and control and safety devices contribute to the correct and stable operation of the system. Each of these components, carefully engineered and designed, ensures that the refrigeration system operates effectively and reliably under various conditions.

Industrial and Domestic Applications of Refrigeration Systems

Refrigeration systems play a very important role in everyday life and industry, with wide-ranging applications. In domestic environments, these systems are mainly used for food storage in refrigerators and freezers, air conditioning, and cooling residential spaces.

In various industries, refrigeration systems play a vital role in preserving quality and extending product life; for example, in the food industry for storing and freezing products, in pharmaceuticals for maintaining storage conditions for medicines and vaccines, in the oil and petrochemical industries for cooling equipment and processes, and also in data centers to manage server temperatures and prevent overheating.

Overall, refrigeration systems provide precise temperature control, increase productivity, reduce material wastage, and maintain product health, playing an indispensable role in improving human life quality and industrial performance.

Maintenance, Problems, and Optimization of Refrigeration Systems and Ways to Increase Efficiency

Proper maintenance of refrigeration systems is of high importance because the stable performance and lifespan of these devices directly depend on the health of their components. Common problems such as refrigerant leaks, compressor failure, clogged filters, and reduced condenser efficiency can decrease performance and increase energy consumption.

To prevent these issues, periodic inspections, cleaning and replacement of worn parts, refrigerant pressure and temperature control, and system performance checks are recommended. Optimizing refrigeration systems using modern technologies—such as employing environmentally friendly refrigerants, installing smart controllers, and optimizing refrigerant flow paths—can significantly increase energy efficiency.

Proper Design of Refrigeration Systems and the Role of Tehran Sarma Engineering Company in this Field

Proper design of refrigeration systems plays a very important role in ensuring optimal performance, increasing energy efficiency, and reducing operational costs. This is because accurate component selection, determining appropriate capacity, and coordination between different system parts are key factors in achieving an efficient and stable refrigeration cycle.

In this regard, Tehran Sarma Engineering Company, utilizing technical expertise and extensive experience in the design and implementation of refrigeration systems, has been able to offer comprehensive and customized solutions that, besides fully meeting customer needs, guarantee high quality and durability while adhering to international standards.

Using advanced design software and a specialized team, this company is capable of executing projects of varying complexity in the best possible way and plays an important role in the development and improvement of refrigeration infrastructure in various industries.

For more information about cold storage construction prices, you can visit the Tehran Sarma website and contact us at 09121906418 and 02177972256.

Refrigeration systems are designed to create and maintain low temperatures in various environments and play a vital role in industrial and domestic processes. Refrigeration units, as the operational parts of these systems, perform the cooling operation. Accurate understanding of refrigeration systems and their applications can lead to optimized energy consumption and increased efficiency across various industries.

Source:

https://www.coldstorageus.com/

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه