General Introduction to the Components of Bitzer Reciprocating Compressor

The Bitzer reciprocating compressor is one of the most widely used pieces of equipment in the refrigeration and air conditioning industry. Due to its high build quality, suitable durability, and acceptable efficiency, the Bitzer reciprocating compressor is extensively utilized in industrial and commercial projects. The components of the Bitzer reciprocating compressor include the cylinder, piston, crankshaft, suction and discharge valves, and the electric motor, each playing an important role in the refrigerant compression process.

The Bitzer reciprocating compressor is recognized as one of the most advanced and reliable devices in the refrigeration and air conditioning sector. Leveraging precise engineering design and high-quality parts, it has secured a prominent position in cooling and heating systems, drawing attention from engineers and specialists thanks to its optimal performance, long durability, and energy-efficient operation.

A complete understanding of the constituent components of the Bitzer reciprocating compressor and the role of each is fundamental for successful operation, maintenance, and repair of these units, ensuring that refrigeration systems maintain stable and efficient performance.

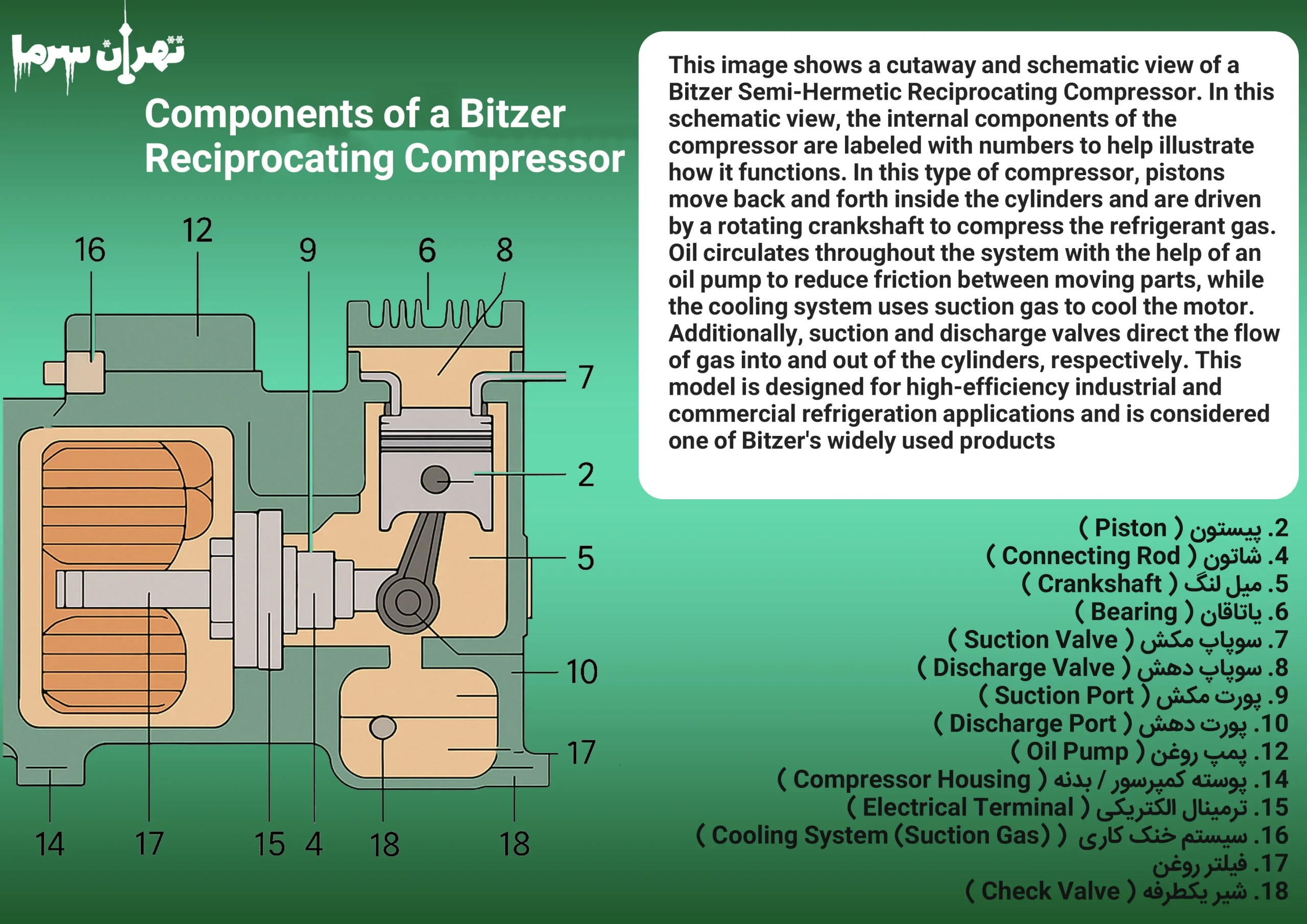

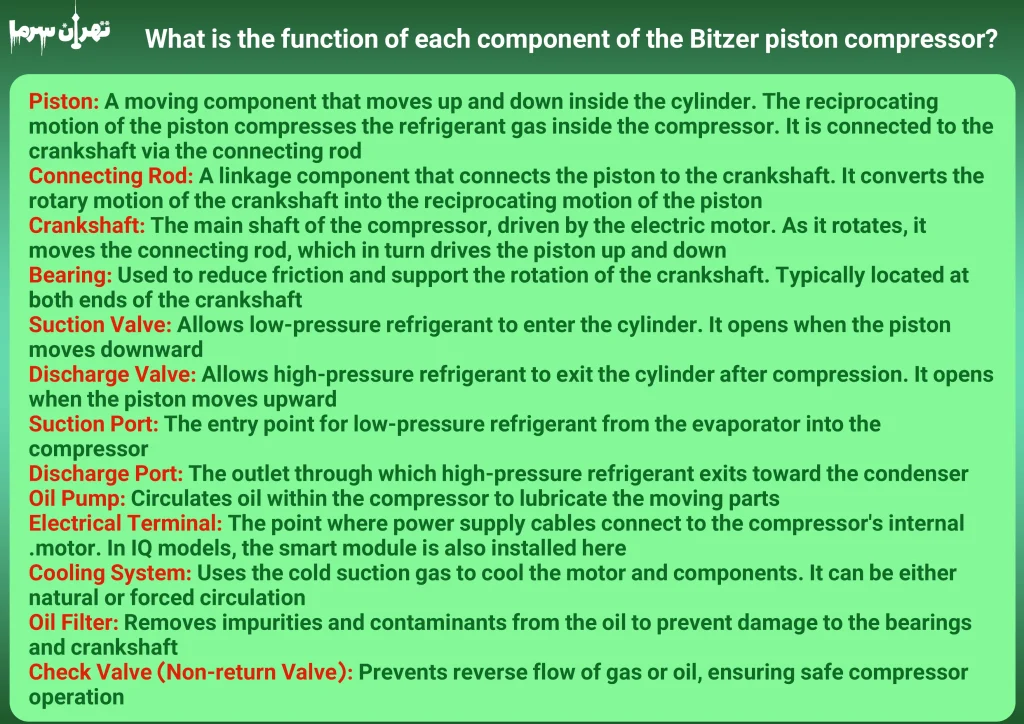

At the core of this compressor, a set of highly precise mechanical parts perform the refrigerant gas compression process. The cylinder and piston, which are the main mechanical components, convert the refrigerant gas from low to high pressure by the reciprocating movement of the piston inside the cylinder.

This movement is driven by the crankshaft and connecting rod, which transform the rotary force of the electric motor into linear motion. The precision in manufacturing these parts and the selection of suitable materials significantly reduce friction, increase efficiency, and improve the compressor’s service life.

In addition to the mechanical parts, the refrigerant flow control system is precisely regulated by the suction and discharge valves. These valves are responsible for allowing refrigerant gas to enter the compressor chamber at the appropriate time and, after compression, directing it towards the cooling system.

The design and operation of these valves prevent backflow of the refrigerant and avoid any leakage or efficiency loss. Their role is crucial in maintaining pressure stability and protecting other components from mechanical damage.

The electric motor, acting as the driving heart of the Bitzer reciprocating compressor, provides the necessary power to drive the crankshaft and pistons. The build quality of this motor and its capability to withstand variable loads and diverse environmental conditions are key factors in ensuring continuous compressor operation. Alongside these, auxiliary components such as bearings, gaskets, and lubrication systems contribute to maintaining mechanical integrity and reducing wear, thereby preventing premature failure.

The integrated and coordinated design of all these components makes the Bitzer reciprocating compressor an efficient and reliable system capable of operating at maximum productivity under various working conditions. A thorough familiarity with these parts and their functions not only enables operators and technicians to quickly identify and resolve issues but also facilitates proper preventive maintenance, significantly extending equipment lifespan.

Consequently, this specialized knowledge not only helps preserve compressor performance but also plays an important role in optimizing energy consumption and reducing operational costs of refrigeration systems.

Detailed Operation of Each Component of the Bitzer Reciprocating Compressor and Its Role in the Compressor

The precise and coordinated operation of each component in the Bitzer reciprocating compressor forms the foundation for the device’s high efficiency and performance. Each part, according to its specific role, effectively and stably carries out a portion of the refrigerant compression process. In this section, the operation of each key compressor component and its impact on overall system performance are examined.

The piston, as the primary compression element, reduces the volume of the refrigerant gas and increases its pressure through its reciprocating movement inside the cylinder. This regular and precise motion ensures a uniform refrigerant flow and maintains pressure balance within the system. The role of the cylinder is to provide a durable and dimensionally precise chamber for the piston’s movement, resisting the alternating pressures and friction caused by contact between the piston and cylinder wall.

The crankshaft and connecting rod serve as intermediaries converting rotary motion into linear motion and play a vital role in the Bitzer reciprocating compressor. The crankshaft transmits the motor’s power into the reciprocating movement of the pistons through its rotation, while the connecting rod connects to the piston and applies this force precisely and evenly. The engineering design of these parts must allow them to withstand dynamic forces while minimizing wear and unwanted vibrations.

The suction and discharge valves control the refrigerant flow and must open and close very precisely to prevent gas backflow and maintain optimal refrigerant circulation in the cycle. These valves react quickly to pressure changes, ensuring that the gas enters the compressor chamber at the proper time and is directed to the condenser after compression. Proper functioning of these valves is highly important, as any malfunction can cause efficiency loss and increased energy consumption.

The electric motor in the Bitzer reciprocating compressor provides the necessary driving force and must be capable of handling variable working conditions. Proper motor operation ensures continuous and uninterrupted crankshaft rotation, which directly affects the overall compressor performance. Additionally, lubrication systems and bearings reduce friction and enhance smooth movement of moving parts, helping maintain the device’s health and longevity.

The coordination and optimal operation of each of these components enable the Bitzer reciprocating compressor to perform with maximum efficiency and minimal failure across various operating conditions. Familiarity with the detailed function of each part and understanding its role in the compressor provide a powerful tool for technicians and engineers to enhance maintenance and repairs, thereby maximizing system productivity.

Materials and Technologies Used in the Construction of Bitzer Reciprocating Compressor Components

The materials and technologies employed in manufacturing the components of the Bitzer reciprocating compressor play a decisive role in the quality, durability, and overall performance of the device. As a pioneer in the refrigeration industry, Bitzer utilizes advanced materials and modern manufacturing technologies to produce products that are not only mechanically strong and stable but also reliably perform under harsh and long-term operating conditions.

For the main mechanical parts such as pistons and cylinders, high-precision aluminum and steel alloys are typically used, providing both desirable mechanical strength and appropriate weight.

Special steel alloys subjected to precise heat treatment processes help increase hardness and wear resistance, thereby reducing friction between the piston and cylinder and significantly extending the parts’ service life. Additionally, advanced surface coatings, such as nitriding or chrome plating, are applied in some areas to enhance resistance against corrosion and wear.

In the crankshaft and connecting rods of the Bitzer reciprocating compressor, the use of high-carbon steels combined with specific heat treatments enables these parts to endure high dynamic forces and cyclic stresses. Precise machining and dynamic balancing technologies help reduce vibrations and improve the smoothness of motion, ultimately boosting the compressor’s efficiency.

The suction and discharge valves are also made from corrosion- and wear-resistant materials, as they are in direct contact with refrigerant gas and subject to frequent pressure changes. Their engineering design, employing advanced molding and machining technologies, increases operational accuracy and extends their lifespan.

Moreover, advanced lubrication systems—including specialized oils and optimized oil pump mechanisms—play a key role in reducing friction and preventing wear of moving components. Modern lubrication technologies are developed not only to minimize friction but also to effectively manage generated heat, preventing the compressor from overheating.

Strict quality control processes and the use of advanced testing and analysis equipment ensure that every component of the Bitzer reciprocating compressor is manufactured to the highest industrial standards and capable of stable long-term performance. This combination of quality materials and cutting-edge technologies is the main reason behind Bitzer compressors’ global success and the widespread trust consumers place in this reputable brand.

Maintenance and Troubleshooting Methods for Bitzer Reciprocating Compressor Components

Maintenance and troubleshooting of Bitzer reciprocating compressor components are of high importance to ensure optimal performance and long service life of the equipment. Regular and periodic inspections allow technicians to identify early signs of failure or performance degradation and prevent serious damages. Special attention during maintenance should be given to the lubrication system, bearing conditions, the health of suction and discharge valves, as well as detailed examination of pistons and cylinders.

Detection of unusual noises, pressure and temperature fluctuations, and changes in compressor performance can be critical indicators of faults in components, which can be diagnosed more precisely using specialized equipment. Successful troubleshooting requires a deep understanding of the operation of each part and their interactions, enabling the technician to analyze symptoms and technical data to pinpoint problems and propose appropriate solutions.

Furthermore, following the manufacturer’s standard guidelines and adhering to safety measures play important roles in preventing human errors and protecting equipment health. Implementing preventive maintenance and timely repairs not only avoids widespread failures but also optimizes energy consumption and reduces the operational costs of refrigeration systems.

Overall, precise and regular maintenance and troubleshooting of Bitzer reciprocating compressor components are the keys to achieving stable operation, extending equipment lifespan, and maintaining optimal efficiency over the long term.

Preventive Tips to Increase Lifespan and Reduce Failures of Bitzer Reciprocating Compressors

Each component of the Bitzer reciprocating compressor plays a vital and complementary role in the refrigerant compression process; the piston reduces gas volume and increases pressure by its reciprocating motion inside the cylinder, while the crankshaft and connecting rod convert the motor’s rotary force into linear motion, enabling piston movement.

The suction and discharge valves regulate refrigerant flow by precise opening and closing, preventing gas backflow and optimizing the compression process. The electric motor provides the necessary driving force, and the lubrication system reduces friction and protects moving parts, helping maintain compressor health and durability. Precise coordination of these components ensures that the Bitzer compressor operates stably with maximum efficiency and minimum wear under varying working conditions.

Choosing the Best Cold Storage Equipment with Tehran Sarma Engineering Company

Selecting the best equipment for cold storage construction is one of the most important stages in designing and implementing industrial and commercial cold rooms, directly impacting product preservation quality and overall system efficiency. Tehran Sarma Engineering Company, with years of specialized experience in designing and supplying advanced cold storage equipment, offers comprehensive solutions tailored to Iran’s climatic and environmental conditions.

By leveraging modern technologies and cooperating with reputable global brands, the company provides high-quality, durable equipment that ensures energy savings, optimal performance, and product safety.

Tehran Sarma’s expert consultation and continuous technical support simplify and secure the process of selecting, installing, and commissioning equipment, guiding customers through every project phase to achieve the best results in constructing reliable and efficient cold storage facilities.

For more information about cold storage equipment, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

In conclusion, the Bitzer reciprocating compressor, utilizing advanced technologies and precise design, holds a special position among refrigeration equipment. The Bitzer brand compressor is a reliable choice for engineers not only due to its high efficiency and long durability but also because of its dependability under various operating conditions. Full familiarity with the components of the Bitzer reciprocating compressor enables maintaining system performance at its best

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه