Review of Technical and Economic Necessities for Building Cold Storage for Fruit

Building cold storage for fruit is one of the most essential measures to increase the shelf life of agricultural products. The design and establishment of cold storage for fruit must be based on the type of fruit, humidity level, required temperature, and desired capacity to prevent premature spoilage. Building cold storage for fruit in Tehran, due to its specific climatic conditions and production and consumption density, requires thorough examination and the use of high-quality equipment and up-to-date international standards.

In recent decades, building cold storage for fruit has become one of the most important links in the value chain of horticultural and agricultural products. In the absence of controlled storage and preservation infrastructure, post-harvest losses of fruits increase significantly, which leads to reduced overall system productivity, damage to food security, and severe price fluctuations in the market.

From this perspective, building cold storage for fruit is not only a technical necessity but also a key factor in achieving economic efficiency, market stability, and sustainable export development.

Technical Review of Building Cold Storage for Fruit

From a technical viewpoint, designing and implementing a specialized cold storage for fruit requires a precise understanding of the physiological processes after harvest. Fruits, as living products, even after picking, still have active metabolism that directly affects their quality, color, taste, texture structure, and storability.

Therefore, building cold storage for fruit must take into account parameters such as optimal storage temperature, allowable relative humidity range, sensitivity to ethylene, and proper ventilation.

For example, the design of suitable cold storage for apples, due to the need for extensive ventilation to control carbon dioxide levels and prevent physiological damage, fundamentally differs from the design of cold storage for grapes or citrus fruits. Failure to comply with physiological requirements may lead to quality degradation, color changes, internal rot, or reduced marketability of the fruit.

Engineering Aspects of Designing and Establishing Cold Storage for Fruit

From a systems engineering perspective, building cold storage for fruit requires the utilization of modern refrigeration technologies, intelligent systems for controlling internal climatic conditions, and real-time monitoring mechanisms. Use of inverter compressors, high-efficiency evaporators, condensers adapted to local climate conditions, and digital controllers such as PLC or HMI are among the components that play a significant role in increasing energy efficiency, precision in environmental condition control, and reducing operational costs.

Additionally, the correct choice of insulation system (such as high-density polyurethane sandwich panels) and appropriate design of cooling load play key roles in optimizing the overall performance of the cold storage.

Building Cold Storage for Fruit in Tehran and Economic Considerations

From an economic standpoint, investment in building cold storage for fruit is regarded as a long-term strategy for resource optimization, waste reduction, and increasing product added value. In many production areas of the country, the absence or shortage of cold storage capacity leads to sudden and concentrated supply of fruits during harvest season, resulting in price crashes, producer losses, and market instability.

In contrast, utilizing specialized cold storages enables precise scheduling of supply, maintaining quality through off-seasons, and even strategic storage for export purposes. Moreover, cold storages provide the necessary infrastructure for precise packaging and sorting, which significantly enhances the commercial value of fruits in domestic and foreign markets.

Building cold storage for fruit should be considered a strategic necessity in agricultural development policies, food security, and export-oriented economy. Without the development of refrigeration infrastructure, agricultural development, especially in horticulture and fruit production, will be vulnerable to climate changes, market fluctuations, and global competitive pressures. Therefore, integrating technical engineering knowledge with precise economic analyses and supportive policymaking is essential for sustainable success in this field.

Types of Technologies Used in Designing and Establishing Cold Storage for Fruit and Their Impact on Product Shelf Life

The design and establishment of cold storage for fruit are directly linked to technologies whose main objective is to preserve the quality, freshness, and storability of the product over various time intervals. In recent years, significant advances in cooling technologies, environmental control, and intelligent management have transformed fruit cold storage design standards.

Nowadays, merely creating a cold space is not sufficient; rather, selecting and combining precise technologies with an understanding of the post-harvest behavior of fruits is considered a decisive factor in the successful performance of cold storages.

One of the most important technologies used in building cold storage for fruit is high-efficiency refrigeration systems. Proper selection of screw or scroll compressors, condensers with variable speed fans, and evaporators with uniform air circulation ensures that the cooling load is accurately controlled and prevents the formation of uneven temperature spots.

This temperature uniformity is a critical factor in preventing phenomena such as surface freezing, moisture loss, or fungal growth in sensitive fruits. Technologies such as inverter refrigeration systems also play an effective role in reducing energy consumption and increasing equipment lifespan, especially in cold storages requiring adaptable cooling loads in different seasons.

Among other prominent technologies is the use of advanced digital controllers for monitoring and precise adjustment of temperature, relative humidity, air circulation speed, and even respiratory gas levels.

Many fruits like apples, kiwis, and pomegranates, when stored in controlled atmosphere (CA) conditions with low oxygen and relatively high CO₂ levels, achieve significantly extended shelf life. Implementation of Modified Atmosphere Packaging (MAP) or Controlled Atmosphere systems in cold storages, especially for export products, is today considered a necessity.

Insulation is also an integral part of the technologies used in building cold storage for fruit. Using high-density polyurethane sandwich panels with complete sealing plays an important role in maintaining internal temperature and reducing heat exchange with the environment. This not only stabilizes the storage conditions for the product but also directly contributes to lowering energy costs.

Furthermore, proper design of the ventilation and internal air circulation system, using smart fans and engineered ducts, plays a vital role in creating a uniform environment free from excess moisture. This is especially important for fruits sensitive to mold and decay such as grapes, cherries, and strawberries. With proper air circulation and control of airflow speed and direction, not only is moisture accumulation prevented, but the natural respiration process of fruits is also better managed.

The design and establishment of cold storage for fruit is considered successful when all the employed technologies are selected with the goal of creating precise, stable, and controllable environmental conditions. The intelligent integration of refrigeration equipment, environmental control systems, thermal insulation, and energy management infrastructure not only significantly increases the shelf life and quality of fruits but also transforms the cold storage into a strategic tool within the modern agricultural supply chain.

Specialized Parameters in Engineering Design for Building Cold Storage for Fruit with Stable and Optimal Performance

Engineering design for building cold storage for fruit is a complex and multi-layered process that requires a precise understanding of the physiological needs of horticultural products combined with technical principles, refrigeration engineering, and sustainable operational requirements.

Contrary to the common misconception that building a cold storage means just creating a cool space, the reality is that stable and optimal cold storage performance is only achieved when its design is based on specialized and scientific parameters. Any mistake or negligence during the design phase will lead to fruit quality degradation, increased energy consumption, or instability in cold storage operation.

The first and most fundamental parameter in design is the cooling load; a precise calculation that determines how much heat the refrigeration system must absorb and dissipate from the space and products to maintain the desired temperature.

This calculation must be based on various factors such as the incoming fruit temperature, frequency of door openings, heat transfer through walls and ceilings, heat load from lighting and internal equipment, and the respiratory heat of the products. The accurate cooling load forms the basis for selecting key equipment like compressors, evaporators, and condensers.

The next important parameter is the appropriate temperature and humidity profile for the fruits. Depending on their type, ripening stage, and post-harvest behavior, fruits require a specific range of temperature and humidity. The cold storage design must ensure that these conditions are uniformly maintained throughout the space.

To achieve this, the choice of internal ventilation system, evaporator placement, and rack or pallet arrangement must be done with precise engineering and airflow modeling. Turbulent airflows or uneven hot and cold spots may cause localized spoilage or increased risk of fungal and mold growth.

Moreover, the type of thermal insulation and structural details of the building play a decisive role in the stable performance of the cold storage. Using polyurethane sandwich panels of appropriate thickness, complete elimination of thermal bridges at joints, sealing of gaps, and prevention of air leaks are critical design elements. Any defect in these areas results in moisture or heat ingress, increased cooling load, reduced efficiency, and temperature fluctuations.

Designing an intelligent control system and continuous monitoring of parameters is also a requirement for modern cold storage. Using digital controllers capable of monitoring temperature, relative humidity, CO₂, and even ethylene in some applications allows the refrigeration system to be automatically and optimally adjusted. When the goal is long-term or export storage of fruits, this level of precision in environmental control is decisive for the final product quality.

In engineering design of cold storage for fruit, a systemic and integrated view of all components is necessary. Selecting equipment based solely on capacity or brand is not sufficient; the interaction among different components, adaptability to seasonal changes, ease of maintenance, and compatibility with local infrastructure must also be considered.

Such an approach not only ensures long-term stable and optimal cold storage performance but also reduces operating costs, preserves investment, and enhances user satisfaction.

Executive Standards, Key Equipment, and Safety Considerations in the Process of Building Cold Storage for Fruit

In the process of building cold storage for fruit, adherence to international and national executive standards, including health, safety, and energy efficiency requirements, plays a determining role in the final quality of the project. Key equipment such as refrigeration compressors, evaporators, condensers, and control systems must be selected from reputable brands with precisely engineered capacity to ensure optimal performance and product preservation.

Special attention should also be paid to thermal insulation using standard sandwich panels, internal air conditioning systems, and moisture-resistant flooring as part of the structural requirements. Alongside these, safety considerations such as installation of refrigerant gas leak alarms, emergency ventilation, electrical protection, and rapid evacuation capabilities in critical situations must be incorporated in the design to provide a safe, stable environment compliant with global standards for fruit storage.

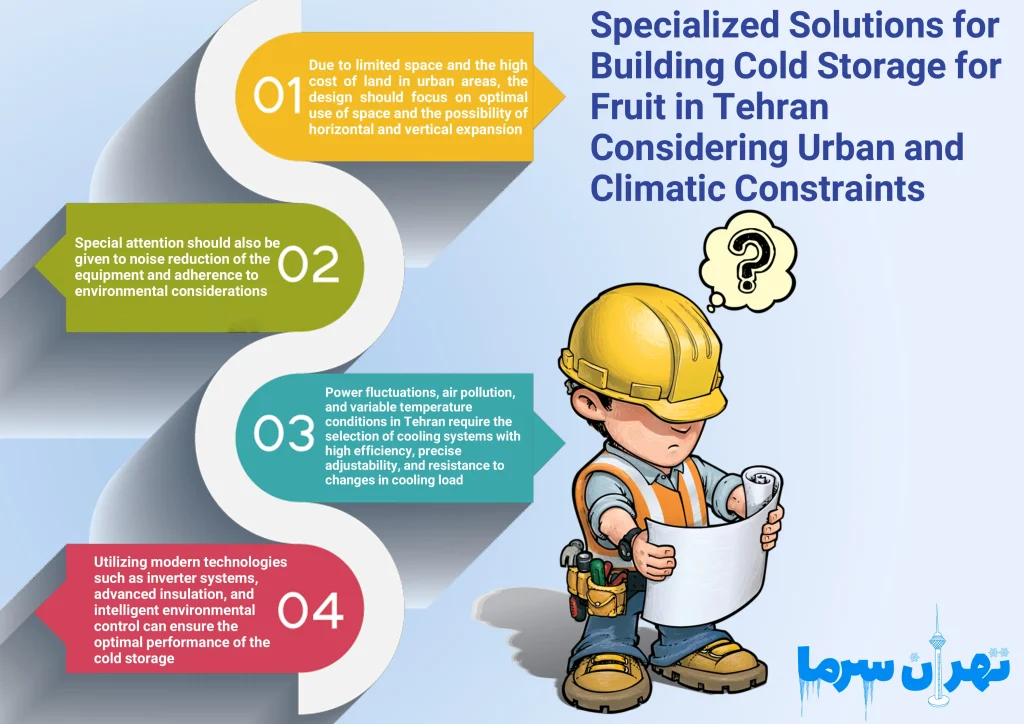

Specialized Solutions for Building Cold Storage for Fruit in Tehran Considering Urban and Climatic Constraints

Building cold storage for fruit in Tehran, given the specific urban constraints and unique climatic conditions of the region, requires the application of specialized solutions and precise engineering. Due to limited space and high land costs in urban areas, the design must focus on optimal space utilization and the possibility of both horizontal and vertical expansion. Attention must also be paid to noise reduction of equipment and environmental considerations.

Moreover, Tehran’s power fluctuations, air pollution, and variable temperature conditions necessitate the selection of high-efficiency cooling systems with precise adjustability and resistance to changes in cooling load. Utilizing advanced technologies such as inverter systems, advanced insulation, and intelligent environmental control, along with precise energy management planning and use of renewable energy sources, can ensure optimal cold storage performance and effectively manage Tehran’s climatic and urban challenges.

?Why Choose Tehran Sarma Engineering Company for Building Cold Storage for Fruit

Tehran Sarma Engineering Company, with years of specialized experience in designing and building cold storage for fruit, is recognized as one of the pioneers in the country’s refrigeration industry. It has successfully combined up-to-date technical knowledge, use of modern technologies, and strict adherence to international standards to deliver projects with stable and optimal performance.

The company boasts an experienced engineering team providing comprehensive consultancy services from the needs assessment stage through installation and commissioning. With a focus on health, safety principles, and energy management, it prioritizes quality assurance and customer satisfaction.

Moreover, Tehran Sarma understands Tehran’s unique climatic and urban challenges and offers specialized and customized solutions that meet diverse market needs and local conditions. Therefore, choosing this company can be the key to success and maximum efficiency in cold storage building projects for fruit.

For more information about cold storage construction pricing, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

Building cold storage for fruit plays a crucial role in maintaining freshness and preventing product loss. Design and establishment must ensure appropriate temperature and humidity conditions for each fruit type. Especially in Tehran, due to high market demand and climatic conditions, precise planning and the use of up-to-date technologies are required.

Source: https://www.onelineage.com/

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه