Complete Review of Danfoss Ball Valve Components and the Role of Each in Refrigeration System Operation

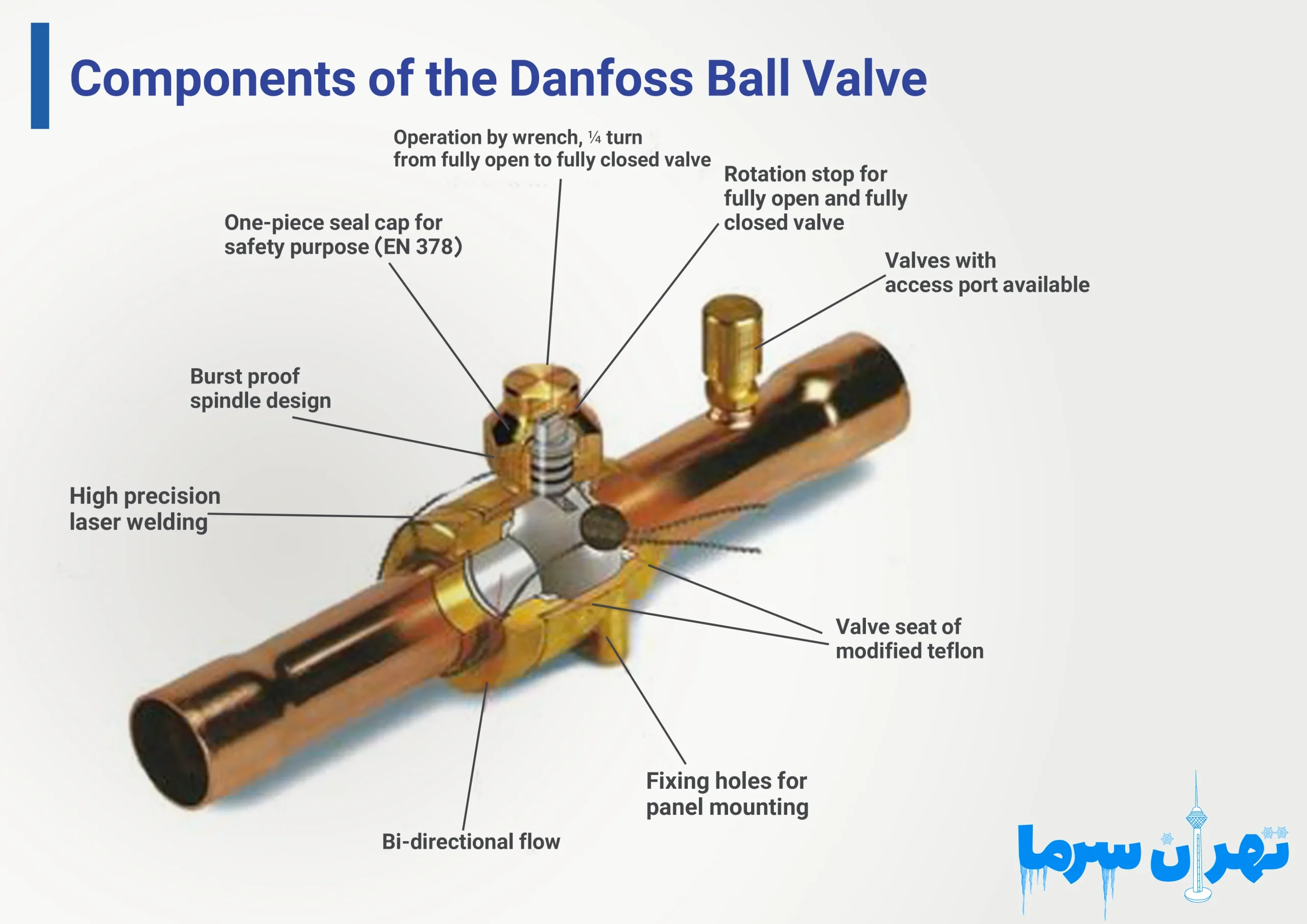

The Danfoss ball valve is one of the most important components used in refrigeration and air conditioning systems. The role of the Danfoss ball valve in these systems is to quickly and safely shut off or allow the refrigerant flow, a feature that increases efficiency and facilitates servicing and maintenance operations. The components of the Danfoss ball valve include a durable brass body, a seat made of modified PTFE (Teflon), a burst-proof spindle, and access ports for charging or evacuating the system.

- Body

The main body of the Danfoss ball valve is made of steel or brass with an anti-corrosion coating to resist pressure and corrosion. The body is designed to allow refrigerant flow with minimal pressure drop. The strength of the body directly affects the overall safety and durability of the valve, especially in systems exposed to temperature fluctuations and high pressure. - Internal Ball

The ball inside, usually made of stainless steel or resistant alloys, plays the main role in opening and closing the flow path. This ball rotates 90 degrees (¼ turn) to open or close the fluid passage. Its smooth and precise surface ensures a complete seal and reduces leakage, which is very important to maintain refrigeration system efficiency. - Valve Seat

The seat is typically made from PTFE (Teflon) or similar materials that resist corrosion, temperature, and pressure. This part creates a complete seal between the ball and the body. The quality of the seat directly impacts internal leakage prevention and maintaining proper system pressure. - Handle & Rotation Mechanism

The valve handle allows the user to easily open or close the valve with a single 90-degree turn. Some models feature a rotation stop to prevent over-opening or over-closing. Additionally, some handles can be locked to increase system safety. - Burst-Proof Spindle

The spindle, which transmits motion from the handle to the ball, is designed in newer models to resist cracking and breaking. This feature prevents sudden refrigerant leaks and maintains system safety in critical conditions. - Seal Cap

The seal cap, usually made of durable plastic or PTFE, prevents moisture or contaminants from entering the valve. In some models, this cap is designed as a single piece to comply with safety standards such as EN 378. This part is very important for ensuring long-term valve performance. - Access Port

Some models include a special port for refrigerant charging or evacuation. This port allows servicing and maintenance without fully opening the system. This feature makes inspection and testing easier in Danfoss ball valves.

Each component of the Danfoss ball valve plays a specific role in ensuring the safe, effective, and stable operation of refrigeration systems. Precise design and the use of high-quality materials have made Danfoss ball valves a reliable choice in various industries. Understanding these components is essential for installers, technicians, and engineers working in refrigeration, helping extend equipment lifespan and reduce maintenance costs.

Explanation of the Role of Danfoss Ball Valve in Refrigeration Systems

The Danfoss ball valve is one of the most important control components in refrigeration and air conditioning systems, playing a fundamental role in managing refrigerant flow. These valves, manufactured with a simple yet very precise design, are responsible for opening or closing the fluid flow in refrigeration lines and are especially critical during repair, service, or system adjustment.

Ball valves are installed in different parts of the system to isolate components or paths without needing to fully evacuate the refrigerant from the entire system.

The functional structure of the Danfoss ball valve is based on a metal or alloy ball inside the valve body that opens or closes the fluid passage by rotating 90 degrees. This simple, low-friction mechanism allows fast operation with minimal leakage.

One advantage of this design is the low operating force required while still guaranteeing complete sealing of the path, which is especially important in high-pressure systems or sensitive applications.

In refrigeration systems, ball valves are usually installed at accessible points such as compressor inlet/outlet, expansion valve, filter dryer, and other key equipment. These installation points allow technicians to quickly block the refrigerant path during problems and carry out necessary operations without disrupting or damaging the entire system. This feature makes the ball valve an essential tool for system safety and reliability.

Besides flow control, many Danfoss ball valve models include an access port. These ports enable pressure measurement, gas evacuation, or refrigerant charging and play a crucial role in troubleshooting, initial startup, or periodic servicing. These additional features make the valve not just a simple valve but a multifunctional and smart component of refrigeration systems.

Technically, Danfoss ball valves are designed to perform stably against temperature fluctuations, high humidity, and varying pressures. The use of materials like brass, stainless steel, and PTFE increases valve durability and resistance to corrosion, leakage, and mechanical damage. Additionally, the burst-proof spindle design and wear- and heat-resistant seats ensure reliable long-term operation.

The Danfoss ball valve is not just a simple mechanical part for opening and closing flow paths but plays a key role in system safety, efficiency, and stable operation. Without this component, controlling and managing refrigerant flow, especially in emergencies or service times, would be very difficult and risky. Therefore, using high-quality ball valves, especially from reputable brands like Danfoss, is a fundamental principle in designing and maintaining modern refrigeration systems.

Technical Analysis of Danfoss Ball Valve Components in High-Pressure Applications

In high-pressure systems, the first critical component is the ball valve body. The body is usually made of hard brass or stainless steel and is designed to withstand high pressures without deformation or leakage.

In models specifically for high-pressure applications, the body thickness is increased and welding or joints are done with high-precision laser technology to provide maximum mechanical strength. This body structure not only withstands internal pressure but also performs stably under sudden pressure shocks.

Next, the internal ball, as the main element in opening and closing the flow path, plays a vital role. In high-pressure applications, this ball is made of alloy steel with a chrome or nickel coating to provide higher resistance to wear, pressure, and corrosion.

The smooth and precise surface of the ball ensures complete sealing without leakage during opening and closing. At high pressures, even the slightest defect on the ball’s surface can cause leakage or pressure drop in the system; therefore, the manufacturing quality of this component is critical.

The valve seat is also a key component of the Danfoss ball valve that experiences significant stress under high pressure. In Danfoss ball valves, the seat is usually made of modified PTFE, which has very high resistance to high temperature, pressure, and chemicals.

In high-pressure models, the seat is designed so that when compressed under pressure, its contact area with the ball increases, thus maintaining a complete seal even under harsh conditions. This special material also prevents irreversible deformation, a factor that plays a key role in the valve’s durability.

Considering the spindle in high-pressure design is also important. Danfoss employs a burst-proof spindle design, where the spindle is constructed to resist breaking or deformation in case of sudden pressure spikes. This design is especially vital to prevent sudden leaks or fluid discharge, as any failure in this area can lead to serious accidents or complete system shutdown.

On the other hand, the seal cap and internal washers in the Danfoss ball valve also play a complementary role in maintaining valve safety. Under high pressure, the stress on connection points is very high, and without proper sealing caps and seals, the risk of leakage increases. In Danfoss ball valves, these components are designed as integrated parts and comply with high safety standards such as EN 378 to ensure reliable operation even in critical conditions.

Another notable feature in high-pressure models is the access ports capable of withstanding high pressure. These ports, designed for charging, evacuation, or pressure measurement, are manufactured with multilayer sealing and precise threading to prevent any leakage or pressure drop during use. These features make Danfoss ball valves not only flow control tools but also precise instruments for measurement and testing.

Besides the physical components, the installation and maintenance of these valves also affect their performance under high pressure. The precise mounting holes on the body allow technicians to securely fix the valve on panels or chassis, preventing any vibration or positional change that could cause cracks or leaks.

The components of Danfoss ball valves in high-pressure models are designed to withstand harsh operating conditions including pressure, temperature, and transient fluctuations, providing stable, safe, and reliable performance. Choosing these valves for industrial applications not only reduces the risk of leakage and failure but also increases the overall lifespan of the refrigeration system.

Impact of Danfoss Ball Valve Component Quality on Refrigeration System Durability and Safety

The quality of Danfoss ball valve components plays a very important role in the durability and safety of refrigeration systems. Using high-quality, standardized ball valves ensures stable system performance and prevents sudden leaks or failures.

This not only extends equipment life but also guarantees overall system safety, preventing potential hazards such as gas leaks or pressure drops. Therefore, selecting high-quality Danfoss ball valves is a key factor for optimal efficiency and safety in refrigeration systems.

Maintenance and Repair of Danfoss Ball Valve Components: Practical Tips for Technicians

Maintenance and repair of Danfoss ball valve components are very important because these parts play a key role in controlling fluid flow in refrigeration systems, and any defect or failure can reduce system efficiency and even cause safety issues.

For technicians, familiarity with practical maintenance tips is essential; these include periodic inspection of the valve’s physical condition, regular cleaning to prevent clogging and contamination buildup, using appropriate tools for proper opening and closing, and ensuring the integrity of connections and seals.

Also, following the Danfoss manufacturer’s service and replacement guidelines helps maintain the valve’s optimal performance and extends its service life. Adhering to these tips not only prevents sudden failures but also optimizes energy consumption and reduces long-term repair costs.

Why Choose Tehran Sarma Engineering Company for Selecting the Best Parts and Options for Cold Storage Construction?

Tehran Sarma Engineering Company, as a pioneer in cold storage construction, utilizes high technical expertise, extensive experience, and premium quality parts and equipment, making it the best choice for selecting suitable components and solutions in this industry.

The company precisely identifies the needs of each project and offers specialized consulting to ensure all parts are optimally selected according to environmental conditions and expected performance. Additionally, Tehran Sarma provides continuous technical support and adheres to international standards to guarantee that constructed cold storages have unparalleled durability, energy efficiency, and safety, supporting customers to achieve the best results.

For more information about cold storage construction pricing, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

In industrial and commercial refrigeration systems, Danfoss ball valves are widely used due to their high quality and reliable performance. The role of Danfoss ball valves is to precisely control refrigerant flow and allow quick shutoff without damaging the system. Reviewing the components of Danfoss ball valves reveals their robust design, effective sealing, and easy installation—all contributing to improved overall system performance.

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه