General Introduction to Danfoss KP1 Low Pressure Switch

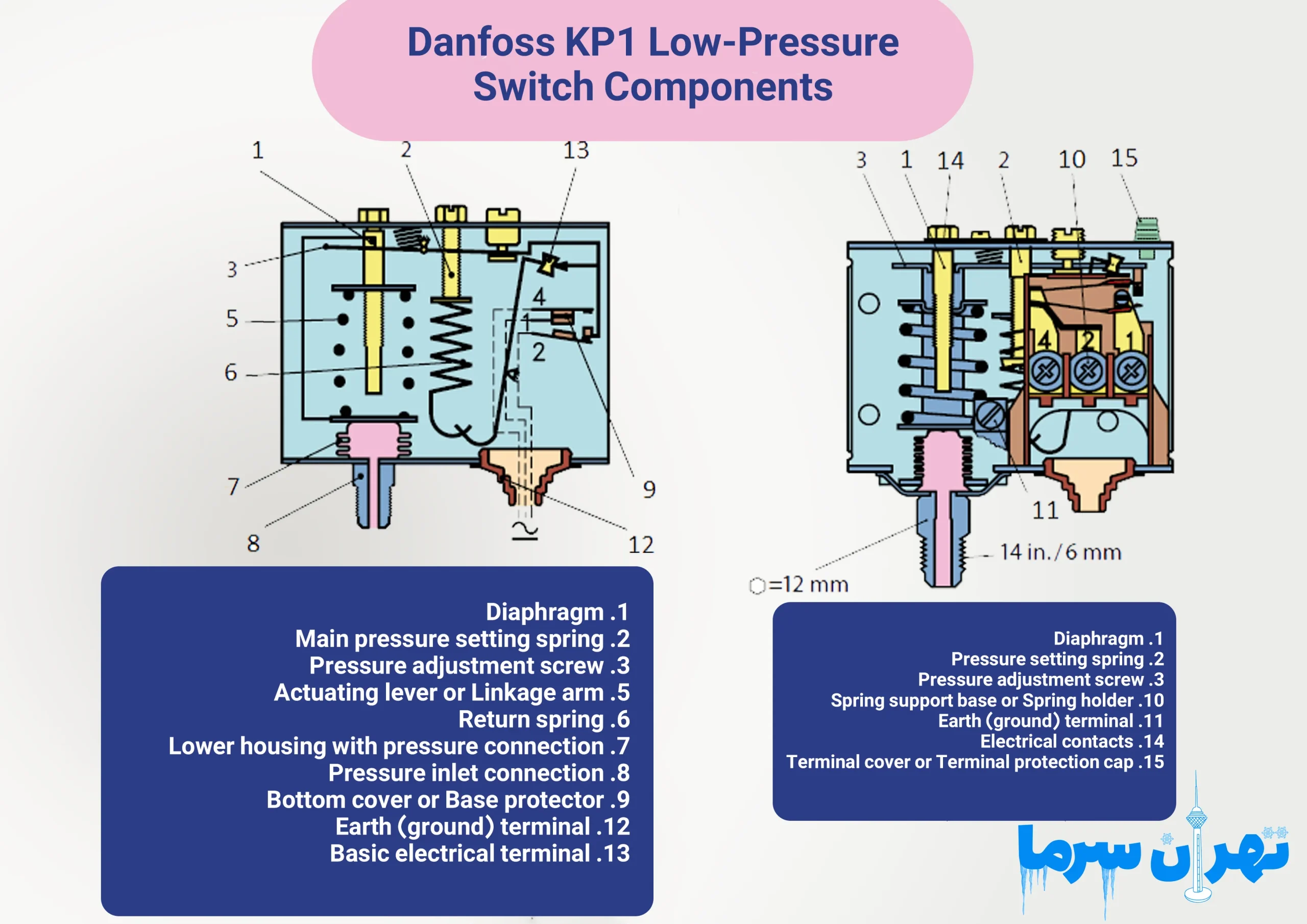

The Danfoss KP1 low pressure switch is one of the key components in refrigeration and air conditioning systems, responsible for controlling and protecting the low-pressure side of the circuit. The components of the Danfoss KP1 low pressure switch include the diaphragm, pressure adjustment spring, adjustment screw, mechanical lever, and electrical contacts, each playing an important role in the proper functioning of the device. Examining the components of the Danfoss KP1 low pressure switch from an internal structural perspective is important.

The Danfoss KP1 low pressure switch is a key and widely used device in refrigeration and air conditioning systems, whose main task is to control the low pressure of the refrigerant gas in the refrigeration circuit and protect the compressor’s operation. This part falls into the category of mechanical control devices, and its operation is based on pressure changes within the circuit and a mechanical response to those changes.

When the suction pressure falls below the defined range, the switch activates and cuts off the compressor’s electrical current to prevent damage. The importance of this function is undeniable in systems that operate continuously, especially in the food, pharmaceutical, and cold storage industries.

The KP1 low pressure switch is a product of Danfoss, one of the most reputable and leading global companies in manufacturing industrial and control equipment. This model’s design ensures not only precision in operation but also high durability, maintaining performance under various climatic and environmental conditions.

Its simple yet precise mechanical structure allows continuous operation without frequent maintenance. This feature has made the KP1 one of the top choices for specialists in industrial and commercial refrigeration systems.

Other important features of the Danfoss KP1 low pressure switch include full compatibility with various refrigerants, resistance to moisture, vibration, and environmental pollution, as well as a compact design and ease of installation.

Due to its engineered design and high manufacturing quality, this device usually does not require recalibration, and with one correct adjustment, it can provide stable and reliable operation for many years. This aspect is especially valuable in large projects with numerous units and backup systems.

Another important point regarding the KP1 low pressure switch is its precise adjustability. This device has pressure cut-out and cut-in adjustment screws that allow technicians to configure the device according to the exact needs of the system and environmental working conditions.

This level of control is particularly important in systems where high pressure fluctuations or energy consumption must be maintained within a precise range. In fact, a proper KP1 adjustment can be the difference between a high-efficiency system and a costly, failure-prone system.

Overall, the Danfoss KP1 low pressure switch should not be regarded merely as an auxiliary tool, but rather as a vital part of the safety and efficiency strategy in refrigeration systems. With its precise operation, high reliability, and design aligned with industrial requirements, this device is a smart choice not only technically but also economically.

With the help of this component, costly failures can be minimized, main equipment like compressors protected, and the useful life of the system significantly extended.

Features and Technical Specifications of Danfoss KP1 Low Pressure Switch Components

The Danfoss KP1 low pressure switch, as one of the most widely used low-pressure switches in refrigeration and air conditioning systems, is notable not only for its control performance but also for the precise design of its components and high build quality, which have drawn the attention of experts in this field.

Each component in this device is designed with a specific purpose, and together they coordinate perfectly to ensure safe and stable operation. The overall structure of this device offers fast response, high accuracy, and long-term durability simultaneously.

At the heart of this system lies the pressure-sensitive diaphragm. This diaphragm is usually made from stainless steel or corrosion-resistant alloys and its primary function is to detect pressure changes in the suction circuit. With increasing or decreasing pressure, the diaphragm bends, and this mechanical movement is transferred to other parts to ultimately open or close the electrical contacts. The quality and precision of this diaphragm directly affect the sensitivity and correct function of the device.

Another vital component in the KP1 structure is the pressure adjustment spring. This spring, with its restoring force, provides resistance against diaphragm movement, and its precise adjustment determines the switch’s operating pressure range.

Users can manually and accurately adjust the cut-out and cut-in pressures via the pressure adjustment screws connected to this spring. These screws are designed so that even in industrial environments subject to vibration or fluctuation, their positions do not change and the settings remain stable.

The electrical contacts in the Danfoss KP1 low pressure switch play a key role in sending the cut-off or connection command to the compressor. These contacts are made from alloys resistant to sparking, corrosion, and high temperatures.

The operation mechanism of these contacts is designed to react instantaneously and precisely in critical situations to prevent serious damage to equipment. The mechanical lever also acts as an interface between the diaphragm and the contacts, responsible for transferring movement with high accuracy.

Other important components of this device include the spring holder base, terminal protective cover, and earth connection for electrical safety. The spring base is designed to prevent the spring’s position from changing over time. The terminal protective cover, besides mechanical protection, prevents moisture, dust, and environmental damage from entering internal parts. Additionally, the earth connection ensures safety against potential leakage currents or faulty grounding.

Overall, the internal component structure of the Danfoss KP1 low pressure switch is designed based on precise engineering principles and high-quality raw materials. This combination makes the KP1 stand out not only in technical performance but also in durability, safety, and reliability. Accurate knowledge of these components is essential and very practical for technicians and engineers involved in installing, adjusting, or maintaining these devices.

Operation and Adjustment of Danfoss KP1 Low Pressure Switch

The operation of the Danfoss KP1 low pressure switch is based on simple yet precise mechanical principles. This low pressure switch is designed to continuously monitor the refrigerant gas pressure in the compressor suction line and, if this pressure drops excessively, it interrupts the electrical current to prevent the compressor from operating under dangerous conditions.

The importance of this function lies in the fact that a drop in suction pressure can indicate refrigerant leakage, blockage in the circuit, or malfunction of the compressor, which if ignored, can lead to serious damage to the refrigeration system.

Inside the KP1 low pressure switch, there is a pressure-sensitive diaphragm directly connected to the refrigeration suction circuit. When the pressure falls below the set value, the diaphragm deforms, and this change is transferred via a mechanical lever to the spring assembly and electrical contacts.

Through this mechanism, the compressor’s electrical current is cut off to prevent unsafe operation. When the pressure returns to normal levels, the diaphragm returns to its original position, allowing the circuit to reconnect.

Pressure adjustment in the Danfoss KP1 low pressure switch is done via special screws connected to internal springs. These screws are usually located on the device body, and by turning them, the cut-out and cut-in pressures can be precisely set.

The cut-out pressure is the point at which the compressor shuts off, and the cut-in pressure is the point where, after favorable conditions return, the compressor restarts. The difference between these two values, known as the “differential,” is important to prevent frequent on/off cycling of the compressor.

During adjustment, the technician must select appropriate cut-in and cut-out values based on the type of refrigerant, refrigeration system type, evaporation temperature, and operating pressure of the circuit. For example, in a cold storage system using R404A refrigerant, the suction pressure range is typically lower than in residential air conditioning systems. Incorrect selection of these values can cause system malfunction, reduced efficiency, or even compressor damage.

Another important point in adjusting this device is ensuring safety during work. Adjustment must be done when the device is powered off, and after completion, the device’s operation should be verified via pressure testing and a pressure gauge. It is also recommended that after any setting changes, the protective covers of the screws and terminals be reinstalled to prevent dust, moisture, or accidental impacts.

The precise operation and flexible adjustment capability of the Danfoss KP1 low pressure switch make it a powerful tool in managing the performance of refrigeration systems. Mastery of this adjustment method by any professional refrigeration technician not only demonstrates technical knowledge but also guarantees the long-term health and stability of the entire system.

Applications and Benefits of Using Danfoss KP1 Low Pressure Switch in Refrigeration Systems

The Danfoss KP1 low pressure switch, as a vital component in refrigeration systems, has wide applications in protecting and optimizing compressor performance. This low pressure switch, by accurately detecting refrigerant pressure drops, prevents possible compressor damage and thus extends equipment service life.

Furthermore, the use of KP1 improves system safety and reduces maintenance costs by preventing costly failures caused by improper compressor operation.

Additionally, the precise cut-in and cut-out pressure adjustability of this device enables compatibility with various systems and refrigerants, helping to increase the overall system efficiency. These features make it a reliable and efficient choice for use in cold storage facilities, chillers, and industrial air conditioning systems.

Importance of Choosing Quality Equipment like Danfoss KP1 in Building Refrigeration Systems

Selecting quality equipment such as the Danfoss KP1 low pressure switch is of utmost importance in building refrigeration systems because these components not only guarantee precise and stable system performance but also play a vital role in maintaining safety and preventing costly failures.

Using high-quality equipment increases the overall system lifespan, reduces the need for frequent repairs, and improves energy efficiency. Especially in industrial and commercial environments where refrigeration systems operate under heavy load and stress, the quality of control components like the KP1 directly affects productivity and operational costs. Therefore, investing in reputable and standard equipment is a guarantee for reliable and continuous operation of refrigeration systems.

?Why Choose Tehran Sarma Engineering Company for Selecting Refrigeration Equipment

With years of specialized experience in designing, supplying, and installing cold storage equipment, Tehran Sarma Engineering Company is considered one of the most reputable centers in the field of industrial refrigeration, capable of providing the best technical solutions and consultations for selecting the most suitable equipment.

This company, by accurately understanding customer needs and utilizing up-to-date knowledge with a specialized team, ensures that each part and device is selected according to environmental conditions, product type, and cold storage capacity to optimize energy consumption and ensure long-term, reliable system performance.

Working with Tehran Sarma means access to high-quality equipment, professional after-sales services, and continuous technical support that can minimize technical errors and unnecessary costs, ultimately increasing cold storage efficiency and lifespan.

For more information about various cold storage construction equipment, you can visit Tehran Sarma’s website or contact via phone numbers 09121906418 and 02177972256.

The Danfoss KP1 low pressure switch is recognized as one of the most widely used low pressure switches in refrigeration systems and plays a significant role in system safety and optimal performance. Its components, including diaphragm, spring, adjustment screw, and electrical contacts, all work in coordination. Reviewing the components of the Danfoss KP1 shows that this device is a reliable option for pressure control in industrial environments.

Source:

https://www.coldstorageus.com/

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه