Uncategorized

Methods to Reduce Costs in Building an Affordable Cold Storage in Tehran Without Compromising Quality

Building an affordable cold storage is possible when the design, materials, and equipment are carefully selected based on technical principles. Utilizing technologies in the design and installation of affordable cold storage not only reduces initial costs but also increases energy efficiency and the lifespan of equipment. Specialized companies active in this field, relying on engineering knowledge and experience, have successfully completed numerous high-quality affordable cold storage projects in Tehran.

In today’s world, where construction and energy costs have increased significantly, implementing affordable cold storage in Tehran without compromising quality is a major concern for investors and professionals in the food, pharmaceutical, and agricultural industries.

Achieving this goal requires a precise understanding of the factors affecting costs, selecting standard equipment, and employing scientific methods in design and execution. Below, the most important strategies to reduce cold storage costs while maintaining system efficiency and durability are discussed.

Building Affordable Cold Storage and Choosing the Right Type of Cold Storage

The first step in building a cold storage is determining the actual capacity and the type of storage suitable for the project’s needs. Many extra costs arise when the cold storage capacity is considered higher than necessary. For example, short-term dairy storage cold rooms are entirely different from deep-freeze storage units. Selecting the optimal capacity not only saves on initial construction costs but also reduces energy consumption and ongoing expenses.

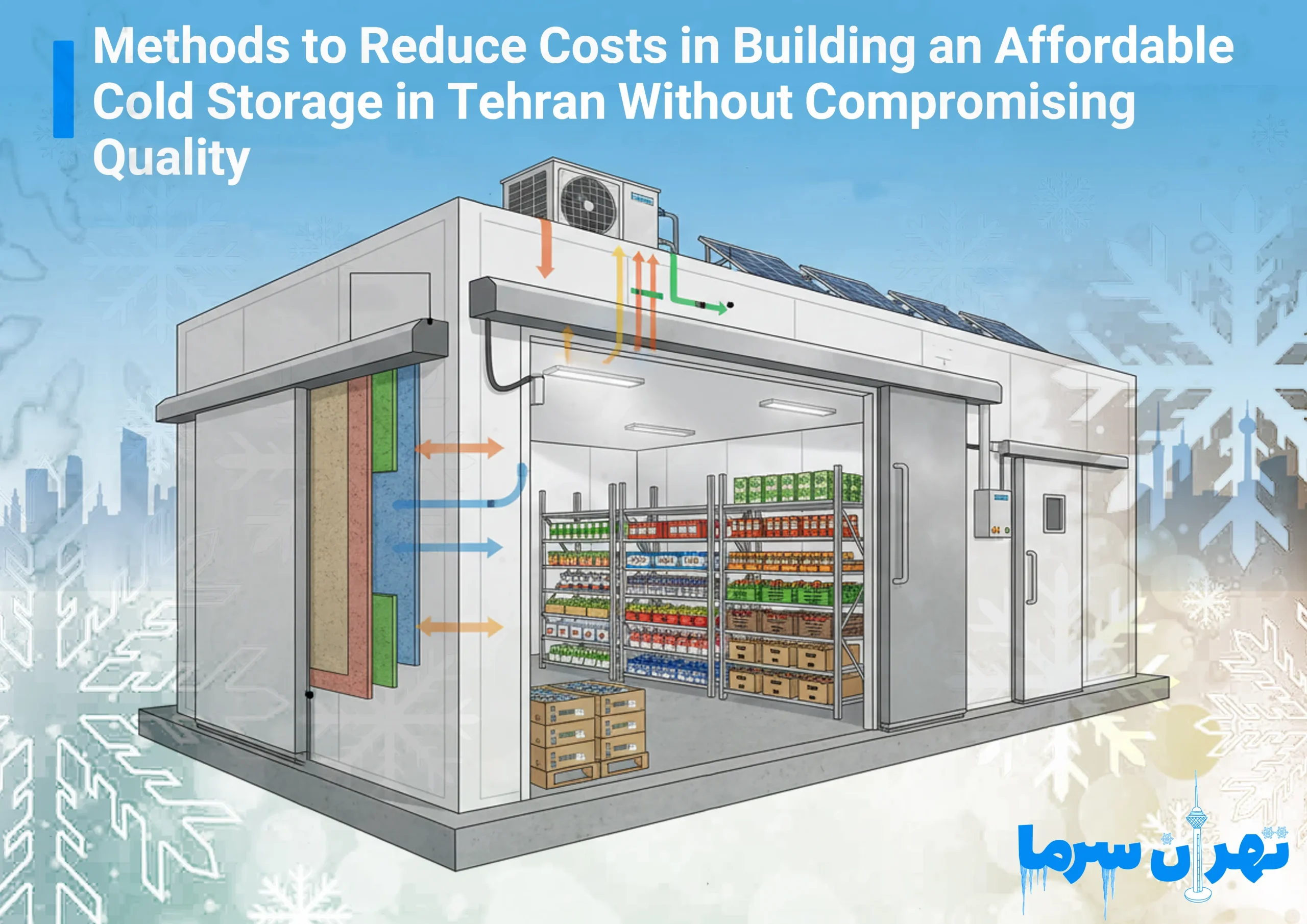

Designing and Installing Affordable Cold Storage Using High-Quality, Cost-Effective Thermal Insulation

One of the most significant factors affecting energy costs in cold storage is heat loss. Using sandwich panels with appropriate thickness and density is key to achieving a cost-effective cold storage design and installation while maintaining quality.

Choosing the right insulation material, such as polyurethane or polystyrene with galvanized or aluminum sheet covering, reduces electricity consumption and extends the structure’s service life. In Tehran’s market, there are numerous suppliers offering standard insulation at reasonable prices, and an informed selection among them can significantly lower the project’s final cost.

Building Affordable Cold Storage in Tehran and Optimizing Refrigeration System Design

One of the most costly components in constructing affordable cold storage in Tehran is the refrigeration system. Proper design of piping routes and the correct selection of compressors, condensers, and evaporators with appropriate capacities play a decisive role in system performance and efficiency.

Experienced engineers often use high-efficiency scroll or piston compressors to maintain stable temperatures while reducing energy consumption. Proper placement of equipment and minimizing piping lengths also prevent energy waste and installation cost increases.

Using Equipment from Reputable and Cost-Effective Brands

A common mistake in cold storage projects is using low-quality or unknown-brand equipment to reduce initial costs. In the long term, this leads to frequent breakdowns, higher energy consumption, and repair expenses. Choosing reputable but cost-effective brands, such as Danfoss, Bitzer, or Tecumseh, is a smart option to balance price and quality.

In Tehran, many reputable refrigeration equipment suppliers offer professional consultation to select the best option according to the project budget.

Proper Execution by Experienced Technical Teams

The final quality of a cold storage largely depends on the execution and installation process. Even the best equipment will not perform adequately if installed incorrectly. Employing technical teams experienced in designing and building affordable cold storage in Tehran ensures the project is executed with minimal errors, energy loss, and cost. Reputable companies usually provide post-installation services and performance warranties, preventing unexpected future expenses.

Choosing the Best Insulation and Materials for Designing and Installing Affordable Cold Storage

In the process of designing and installing affordable cold storage, selecting appropriate insulation and materials is one of the most important aspects that directly impact performance, durability, and final project cost. Cold storage must maintain temperatures within a specific range and prevent heat transfer between the interior and exterior environments.

If not done properly, even the best cooling equipment cannot achieve optimal efficiency, significantly increasing energy consumption and maintenance costs.

A fundamental principle in cold storage construction is using materials that provide proper thermal insulation while being cost-effective in terms of durability, mechanical strength, and price. Today’s market offers a wide variety of materials and insulation, and choosing among them requires awareness of technical specifications, climate conditions, and storage purposes.

In affordable cold storage projects, the goal is usually to balance initial costs with long-term efficiency; in other words, savings should not come at the expense of quality and system performance.

Many modern cold storage units use sandwich panels, consisting of two metal sheets with an insulating core between them. This structure not only prevents heat infiltration but also offers significant advantages in terms of weight, installation speed, and moisture resistance.

The thickness and material of these panels depend on the required temperature and the type of products stored. Galvanized or aluminum sheets are typically suitable for covering these panels due to their high resistance to rust and long lifespan.

For the insulating core, various materials are used, with polyurethane and polystyrene being the most common. Polyurethane, with its very low thermal conductivity, performs better in preventing energy loss, making it one of the most popular choices in affordable cold storage projects.

On the other hand, polystyrene is a more cost-effective option and can be suitable when the storage temperature is not extremely low. It is important that the selected insulation meets the required standards to prevent deformation, moisture absorption, or efficiency loss over time.

Moisture is a critical consideration in cold storage design and installation. Water vapor entering from the outside causes frost formation on walls and reduces cooling efficiency. Therefore, using moisture-resistant coatings, precise sealing of joints, and correct installation of doors and floors complements proper insulation selection.

In professional projects, even minor areas, such as the junction of walls to floors or ceilings, are sealed with special strips to prevent heat and moisture leakage.

Alongside technical characteristics, the availability of materials in Tehran’s market significantly affects final costs. For affordable cold storage design and installation, materials must not only be of good quality but also readily available and easy to transport at minimal cost.

This ensures the project proceeds without delays and keeps ancillary expenses low. Often, collaborating with local suppliers or domestic manufacturers offering standard products is the best way to reduce costs without compromising quality.

Choosing the best insulation and materials for cold storage requires understanding the balance between quality and economic savings. Cost reduction should not mean using cheap, low-quality materials, as this leads to higher electricity consumption, shorter equipment lifespan, and frequent repairs in the future.

Here’s the English translation of your text, keeping the structure, headings, and details intact:

The Impact of Compressor and Condenser Type on the Final Cost of Building Affordable Cold Storage

In the process of building affordable cold storage, the type of compressor and condenser plays a decisive role in the final project cost. These two components, as the heart of the refrigeration system, are responsible for providing and maintaining the desired temperature within the cold storage, and every decision regarding their selection can directly affect construction costs, energy consumption, and equipment durability. In fact, achieving a cost-effective yet efficient cold storage is impossible without choosing the right components.

The compressor, as the main part of the refrigeration cycle, is responsible for compressing the refrigerant gas and creating the necessary pressure difference for heat transfer. The choice of compressor type depends on factors such as required capacity, type of cold storage, operating temperature, and even local climate conditions.

In projects where the main goal is to build affordable cold storage without compromising quality, attention to energy efficiency and compressor durability is crucial. Using modern technology compressors, such as scroll or semi-hermetic models, may have higher initial costs compared to simpler models, but in the long term, they significantly reduce operational costs by lowering electricity consumption and improving system stability.

On the other hand, the condenser, as a heat exchanger, is responsible for cooling and condensing the refrigerant gas, and its role in overall system efficiency is equally important. Selecting the appropriate condenser type for Tehran’s environmental conditions, where summer heat can put significant stress on the refrigeration system, is critical.

In professional projects for designing and building affordable cold storage in Tehran, air-cooled condensers with compact designs and energy-efficient fans are commonly used. These provide stable performance under variable weather conditions while reducing energy consumption.

An important point in cost reduction is the coordination between the compressor and condenser. Even when using the best brands, if the capacities of these two components are mismatched, the system will not operate correctly, leading to increased pressure, energy consumption, and component wear.

Precise engineering in selecting these components, in addition to reducing construction costs, prevents premature repair and replacement expenses. Therefore, collaborating with specialized teams experienced in refrigeration cycle design is a key factor in the success of affordable cold storage projects.

The impact of compressor and condenser selection is not limited to initial costs; it also directly affects the long-term efficiency of the cold storage. Systems built with substandard or low-quality equipment often experience performance decline in a short time, and their maintenance and electricity costs are considerably higher than systems designed with suitable equipment.

Hence, a purely cost-driven approach in equipment selection should not replace engineering decisions, as it ultimately increases the total project cost.

The Role of Proper Layout Design and Equipment Placement in Building Affordable Cold Storage

Proper layout design and equipment placement are crucial in constructing affordable cold storage because even minor errors in space planning or equipment arrangement can lead to increased energy costs, reduced system efficiency, and shorter equipment lifespan.

Choosing suitable locations for compressors, condensers, evaporators, and piping routes should ensure uniform cold airflow throughout the storage space, preventing hot spots or energy loss. Additionally, a well-planned layout allows easy access for equipment maintenance and repair, avoiding extra costs from relocation or complex repairs.

In affordable cold storage projects, paying attention to these details helps minimize initial and operational costs while maintaining quality and optimal performance, turning the investment into long-term efficiency.

The Importance of Experience of Successful Companies in Implementing Affordable Cold Storage Projects

The importance of experience of successful companies in implementing affordable cold storage projects cannot be overstated. This experience ensures that all stages, from design to equipment procurement and installation, are carried out carefully and according to technical standards. Professional companies, with practical knowledge in selecting compressors, condensers, insulation, and materials, can plan projects in a way that reduces initial costs while maximizing energy efficiency and equipment lifespan.

Their experience also allows them to anticipate potential challenges and prevent costly mistakes during construction, ensuring that the final cold storage is not only economical but also stable and reliable. Ultimately, collaborating with such companies ensures that investments yield maximum efficiency with minimal resource waste, and the cold storage operates reliably over the long term.

The Best Method for Building Cold Storage with the Tehran Sarma Engineering Team

The best method for building cold storage is achieved when all stages, from initial design to installation and commissioning, are executed in full coordination between the engineering team and standard equipment.

Tehran Sarma Engineering Company, utilizing experienced specialists, extensive experience in selecting compressors, condensers, insulation, and suitable materials, and adherence to engineering principles in equipment placement, has optimized the cold storage construction process. This ensures that, in addition to cost reduction, the system’s long-term performance is stable and reliable.

Collaborating with this team guarantees that the cold storage is built economically and with high quality, while its operation and maintenance are also energy-efficient and convenient.

For more information on cold storage construction costs, you can visit the Tehran Sarma website or contact 09201906418.

Building affordable cold storage is not merely about reducing costs; it requires precise planning and the selection of standard equipment. Utilizing modern methods in the design and installation of affordable cold storage can minimize energy consumption while maintaining quality. Today, reputable companies, leveraging the expertise of skilled engineers, have successfully executed numerous high-efficiency and competitively priced affordable cold storage projects in Tehran.

Source:

https://ticold.com/

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه