Construction of cold storage and its types

First, let us say that if you are looking to build a cold storage facility and its various types according to modern global standards, our company—with a proven track record in this field—is ready to serve you. From the consultation and design phase to the final commissioning of the cold storage, every step is carried out by our professional team. For more information or to place an order for cold storage construction, you can contact our experts and take advantage of our exclusive services.

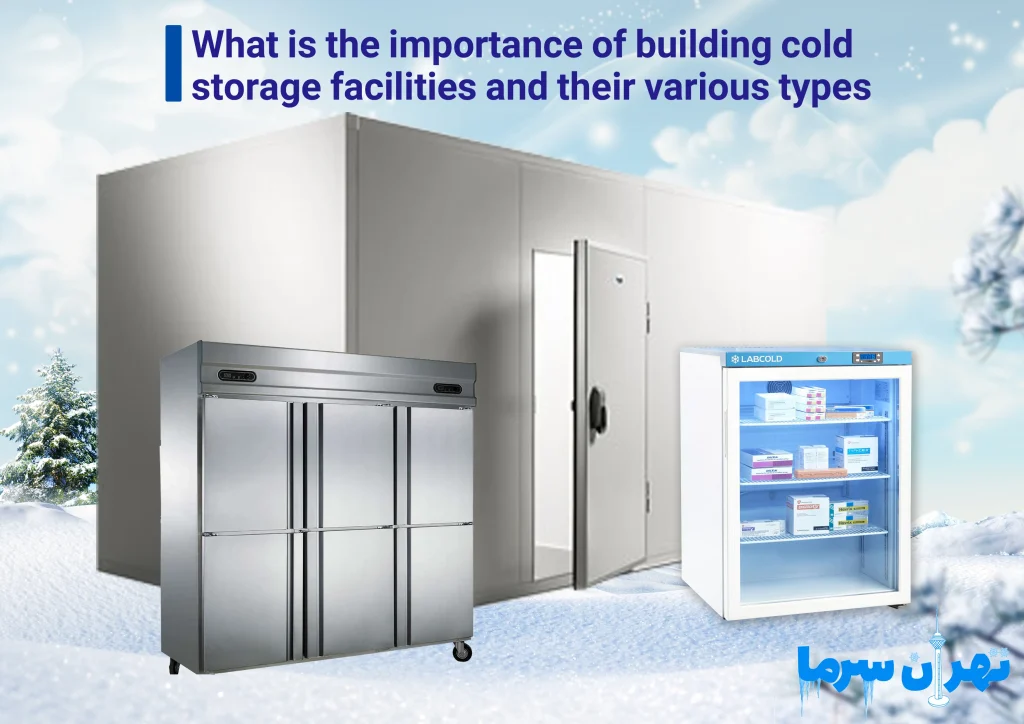

In today’s world, preserving perishable goods is more vital than ever. Whether for pharmaceutical products, food items, or technological components, the ability to maintain a consistently cold and controlled environment is crucial. As such, cold storage solutions have become an essential part of various industries, ensuring that products retain their integrity from production to delivery.

These solutions encompass a wide range of facilities and equipment designed to store goods at specific temperatures.

In this article, along with explaining the different types of cold storage, we will introduce one of the leading companies in the construction of cold storage facilities—so stay with us.

Among the diverse available options are portable refrigerators, freezer units, industrial cold storage rooms, and pharmaceutical-grade cold storage systems. Each type is suited to different needs depending on factors such as temperature range, capacity, accessibility, and energy efficiency.

Furthermore, technological advancements have introduced sophisticated features like real-time monitoring and automated temperature control, which significantly enhance the reliability of these systems in the cold storage construction process.

The Importance of Choosing the Right Cold Storage Solution Cannot Be Overlooked

The importance of choosing the right cold storage solution in the construction of cold storage facilities and their various types cannot be overstated. Businesses must consider that the type, capacity, and technology used in cold storage systems directly impact product quality, reduce waste, and optimize energy consumption.

In industries such as food, pharmaceuticals, agriculture, dairy, and protein products, even the slightest disruption in temperature control can lead to spoilage, loss of economic value, and even legal consequences. Therefore, choosing the appropriate cold storage facility should be based on the precise needs of each business, the type of products, the region’s climate, energy consumption patterns, and projected future capacity.

Cold storage solutions include options such as fixed cold rooms, portable container-type cold storage units, industrial refrigerators, or even hybrid systems—each offering unique features and benefits. A poor or rushed decision without professional assessment can result in high repair and maintenance costs, decreased efficiency, and an increased risk of product loss.

That’s why consulting with specialized engineering companies like Tehran Sarma, with extensive expertise in cold storage construction and its variants, helps business owners choose the most efficient and low-risk cold storage solution.

These factors significantly influence the choice of cold storage and ensure that products are maintained in their optimal condition while simultaneously optimizing operational costs and efficiency. Therefore, understanding the different types of cold storage facilities and their ideal applications is crucial for making informed decisions that align with both product requirements and business goals. Through this article, we’ll provide insights into these different types—serving as a guide through the complexities of cold storage solutions.

Exploring the Various Types of Cold Storage Construction

Cold storage is critical for preserving perishable goods by maintaining specific temperatures to extend their shelf life. Different types of cold storage facilities have been designed to meet the varied demands of industries such as food, pharmaceutical, and agriculture.

Cold Storage Construction and Mobile Refrigerators & Freezers:

These are among the most common types of cold storage facilities, capable of holding a wide range of products. Mobile units are ideal for businesses that require storage of large quantities of perishable goods with frequent access.

Cold Storage Setup and Refrigerated Containers:

Portable and versatile refrigerated containers are used for both storage and transportation. These are ideal for businesses without permanent cold storage infrastructure.

Blast Freezers:

These freezers are essential for rapidly reducing the temperature of products—particularly food—to prevent bacterial growth. They are commonly used in processing plants where fast cooling is a crucial step in production.

Pharmaceutical-Grade Cold Storage:

This category involves precise temperature control and often includes backup systems to ensure consistent cooling. These units are vital for the safe storage of medications and vaccines.

Cold Rooms:

Designed for large-scale storage, cold rooms are typically found in warehouses. They can be customized in terms of size and temperature according to the client’s needs.

Cryogenic Freezers:

Using extremely low temperatures, cryogenic freezers rely on substances like liquid nitrogen or carbon dioxide for cooling. They are ideal for preserving biological samples and are commonly used in scientific research.

Ultra-Low Temperature Freezers and Custom Cold Storage:

These specialized units maintain temperatures between -40°C and -80°C. They are essential in research and medical facilities where storing samples at ultra-low temperatures is required.

Each type of cold storage has distinct features and costs that must be considered alongside the specific storage needs. Choosing the right type ensures energy efficiency, cost-effectiveness, and—most importantly—the integrity of the stored perishable goods.

It’s worth mentioning that Tehran Sarma has years of successful experience in designing and building various types of cold storage. You can confidently entrust your project to our specialists.

Selecting the Right Cold Storage Type for Your Industry

Choosing the correct type of cold storage is vital to ensure goods are kept at optimal temperatures while maximizing efficiency and cost-effectiveness. Several key factors must be considered when selecting the right cold storage solution for a specific industry:

- Capacity and Scalability: Determine the volume of goods that need refrigeration or freezing, and anticipate future expansion. Businesses with fluctuating inventory levels may benefit from modular cold storage systems that can be easily scaled up or down—modular cold storage construction meets this need perfectly.

- Specific Temperature Requirements: Different products require different temperature ranges. For instance, the pharmaceutical industry may need ultra-low freezers, while fruits and vegetables are best kept in slightly chilled environments. It is crucial to build the right type of cold storage for each product category.

- Energy Efficiency: Operating costs for cold storage facilities can be substantial. Choosing energy-efficient units with proper insulation and modern cooling systems can significantly reduce long-term expenses.

- Compliance and Standards: Ensure the cold storage facility complies with industry-specific regulations and standards to maintain product safety and quality.

- Location and Accessibility: Logistics and transportation play a key role. The cold storage facility should be conveniently located to minimize transit time and costs while maintaining product integrity.

- Technology Integration: Advanced monitoring systems can help track inventory, maintain optimal conditions, and alert staff to any temperature deviations in real time.

It’s important to note that understanding the design and operational mechanisms of cold storage facilities is essential for improving the quality of both your products and your overall business performance. But there’s no need to worry—you can rely on the expertise of Tehran Sarma with complete peace of mind.

Industries and the Construction of Cold Storage Facilities and Their Types

- Food and Beverages: Portable refrigerators/freezers, blast chillers, and cold rooms designed for products such as dairy, meat, and frozen goods.

- Pharmaceuticals: Ultra-low temperature freezers, cryogenic storage, and secure climate-controlled equipment for sensitive drugs and vaccines.

- Agriculture: Bulk storage coolers and processing-area chillers for fresh produce.

- Floriculture: Refrigerated display cases and humidity-controlled storage coolers to maintain flower freshness.

- Chemicals: Temperature-controlled storage for hazardous materials to prevent degradation or chemical reactions.

- Data Centers: Cold aisle containment and precision air conditioning systems to cool servers and ensure optimal performance.

With careful assessment of these considerations, industries can identify the most suitable cold storage solutions tailored to their specific needs—ensuring the safety, quality, and shelf life of temperature-sensitive products.

Why Should You Choose Tehran Sarma Engineering Company for Cold Storage Construction

If you are looking to build a reliable, efficient cold storage facility that complies with modern international standards, Tehran Sarma Engineering Company is a smart and professional choice. With years of successful experience in the design, construction, and commissioning of various types of cold storage—including low-temperature, medium-temperature, containerized, and industrial units—this company has earned the trust of numerous reputable brands and industry leaders.

By leveraging a highly skilled team, utilizing original equipment from renowned global brands, adhering strictly to technical and climate-specific requirements, offering specialized consulting before execution, and providing full after-sales support, Tehran Sarma delivers unmatched value to its clients.

By choosing Tehran Sarma, you not only ensure the quality and durability of your cooling system, but also achieve maximum efficiency in energy savings, operational performance, and product preservation.

Feel free to contact us to learn more about cold storage construction pricing.

Source: www.frigosys.com

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه