Thermodynamic Analysis of the Impact of Using HFC Gases in Cold Storage Construction

The use of HFC gases plays a crucial role in constructing cold storage systems by ensuring efficient and sustainable refrigeration. Their application in setting up and installing cold storage units is particularly significant as the optimal performance of refrigeration equipment depends on the precise selection of these gases. A review of the use of HFC gases in cold storage construction highlights their contribution to enhancing equipment performance and extending its lifespan.

1. Application of HFC Gases in Cold Storage and Refrigeration Systems

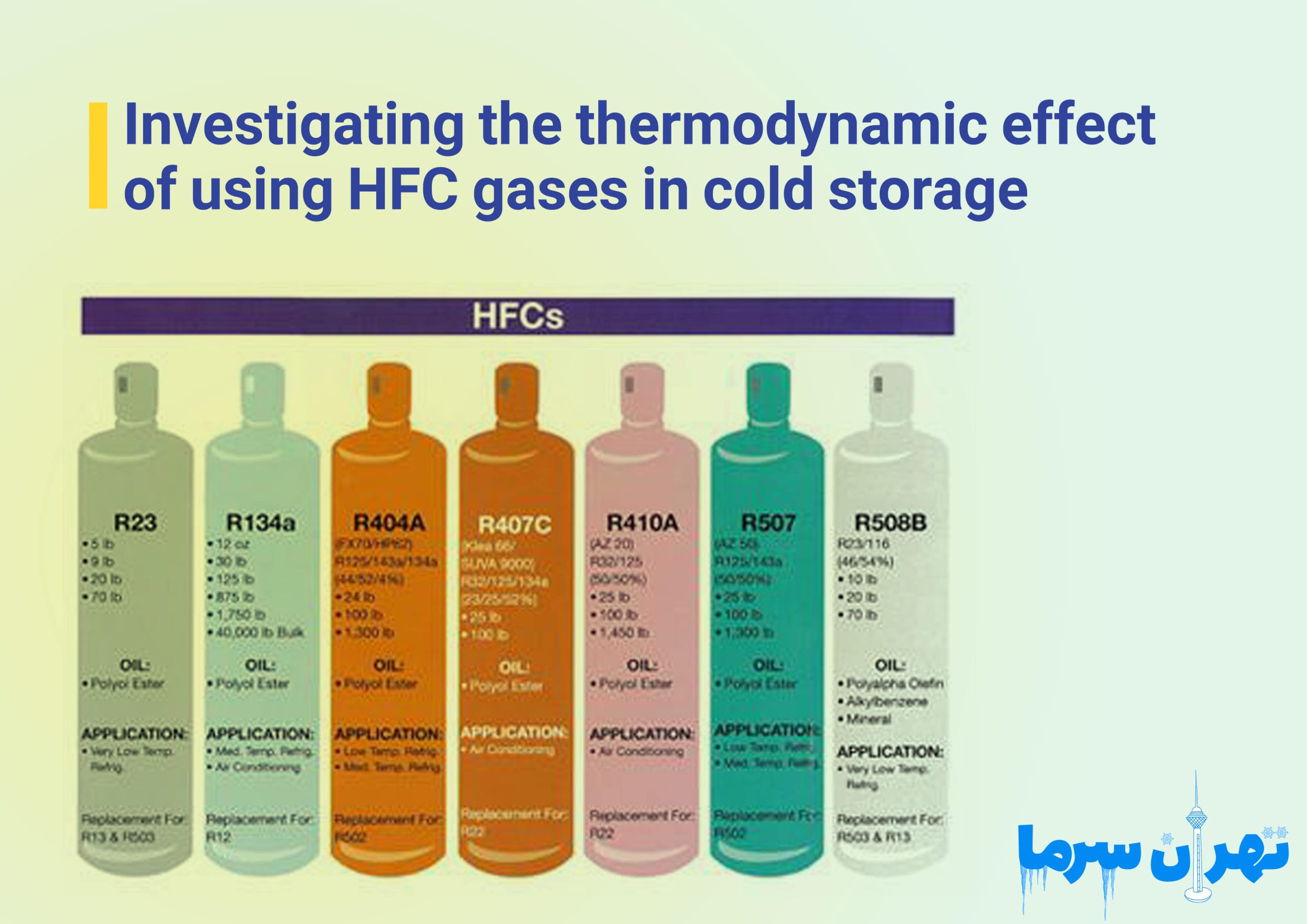

Thermodynamic studies on the use of HFC gases in cold storage construction reveal their essential role in the efficiency of refrigeration systems. HFC gases (hydrofluorocarbons) are widely used in industrial and commercial cold storage due to their favorable thermodynamic properties, including high cooling capacity, appropriate evaporation pressure, and chemical stability.

These gases, introduced as substitutes for harmful gases like CFCs and HCFCs, have proven effective in modern refrigeration systems.

From a thermodynamic perspective, one of the key features of HFC gases is their high heat transfer coefficient and cooling capacity at moderate operational pressures. This characteristic enables compressors in refrigeration systems to operate more efficiently, thereby improving the system’s coefficient of performance (COP). A higher COP means that the input energy is converted into useful cooling more effectively, which directly reduces energy consumption and operational costs.

2. Application of HFC Gases in Cold Storage Installation and Chemical Properties

In addition, HFC gases possess stable chemical properties that reduce the likelihood of leaks or degradation in refrigeration systems over time. This chemical stability, combined with their suitable pressures, plays a significant role in extending the lifespan of cold storage equipment. For instance, R-134a, one of the most commonly used HFC gases, is widely employed in both sub-zero and above-zero cold storage systems due to its physical and thermodynamic characteristics.

Another significant thermodynamic impact of these gases is the reduction in pressure drop within refrigeration systems. Gases with high heat transfer coefficients, such as R-410a, maintain steady flow and reduce pressure loss, thus improving overall system efficiency. This pressure drop reduction is particularly important in large and complex refrigeration systems, such as industrial cold storage units.

3. Evaluation of HFC Gas Applications in Cold Storage Construction

Despite these advantages, it is important to note the challenges associated with HFC gases. These gases have a relatively high global warming potential (GWP), which can have significant environmental impacts. As a result, many countries are striving to reduce the use of HFC gases and replace them with newer alternatives like HFOs, which have a lower global warming potential.

Application of HFC Gases in Improving COP in Modern Cold Storage

The application of HFC gases in constructing modern cold storage systems is one of the key factors in improving the Coefficient of Performance (COP) of these systems. COP is a critical measure of the efficiency of refrigeration systems, indicating the ratio of useful cooling produced to the energy consumed by the compressor.

The higher this ratio, the more efficient and energy-saving the system is. HFC gases, due to their unique chemical and physical properties, have played a significant role as effective refrigerants in improving this metric in modern cold storage facilities.

One of the most important characteristics of these gases is their favorable thermodynamic properties, such as high refrigeration capacity, appropriate operating pressures, and controlled boiling points. These features allow compressors to work at lower pressures, consuming less energy while maintaining optimal cooling output.

For instance, R-410a, one of the commonly used HFC gases, is widely applied in many modern refrigeration systems due to its high heat transfer capabilities. This gas has significantly enhanced COP by reducing the energy requirements of compressors.

Application in Two-Stage Refrigeration Systems and Its Impact on Efficiency

The use of HFC gases in constructing cold storage equipped with two-stage refrigeration systems is a key factor in improving their efficiency. These advanced systems, designed for extremely low temperatures, rely on selecting suitable refrigerants for optimal performance. HFC gases, such as R-134a and R-410a, are primary choices due to their unique physical and chemical properties.

In two-stage refrigeration systems, cooling occurs in two separate cycles: high-pressure and low-pressure. This design reduces thermal load and improves overall system efficiency. HFC gases, with their high cooling capacity and appropriate evaporative pressures, ensure optimal heat transfer between the two stages.

Their use in two-stage systems results in reduced energy consumption and improved COP, making them particularly beneficial for cold storage facilities requiring ultra-low temperatures, such as those used for frozen or pharmaceutical products.

Compatibility with Cold Storage Equipment

HFC gases are compatible with a wide range of modern refrigeration equipment due to their balanced operating pressures and high cooling capacity. Gases like R-134a and R-410a work seamlessly with compressors, evaporators, and condensers, ensuring efficient and reliable operation.

Additionally, the chemical stability of these gases reduces the likelihood of system component damage, extending the lifespan of the equipment. Their compatibility with synthetic refrigeration oils further ensures smooth operation and optimal system performance. However, precise equipment selection and adaptation to the specific HFC gas used are crucial to prevent pressure drops or efficiency reductions, particularly under challenging operating conditions or extremely low temperatures.

Would you like me to expand further on any section or focus on another specific aspect of HFC gases

Safety and Environmental Standards Related to the Use of HFC Gases in Cold Storage Construction

Safety and environmental standards related to the use of HFC gases in cold storage construction are designed to minimize human and environmental risks. From a safety perspective, these standards emphasize the proper use of pressure-resistant equipment and the design of systems with minimal risk of gas leakage. Additionally, installation and operation must be carried out by skilled technicians in compliance with safety protocols.

From an environmental standpoint, limitations such as reducing the amount of HFC gas charge in systems and using refrigerants with low Global Warming Potential (GWP) have been prioritized. International standards such as ASHRAE and the Montreal Protocol provide recommendations for reducing HFC use and replacing them with environmentally friendly refrigerants to maintain the efficiency of cold storage systems while minimizing environmental impact.

The Use of HFC Gases in Cold Storage Construction by Tehran Sarma Engineering Company

Tehran Sarma Engineering Company, as one of the pioneers in designing and constructing industrial and commercial cold storage facilities, utilizes HFC gases in its refrigeration systems to provide both optimal performance and high efficiency for its clients.

By employing HFC gases such as R-134a and R-410a in the cold storage construction process, the company designs cooling systems with high capacity and low energy consumption, while paying special attention to safety and environmental standards.

The company’s engineers, leveraging cutting-edge technologies, implement systems that not only reduce operational costs but also extend the lifespan of cold storage equipment. This approach has positioned Tehran Sarma as one of the reputable companies in building cold storage facilities using advanced and sustainable refrigerants.

For more information about the costs of constructing various types of cold storage, you can visit Tehran Sarma’s website or contact them at 09121906418 and 02177972256.

The use of HFC gases in cold storage construction is significant due to features such as high efficiency and a lower environmental impact. Additionally, using HFC gases in cold storage installation and commissioning optimizes equipment performance and reduces maintenance costs. A review of the use of HFC gases in cold storage construction shows that these gases are an excellent choice for balancing technical efficiency and environmental considerations.

Source: Daikin Industries

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه