What is a Cold Storage Evaporator? Applications and Types

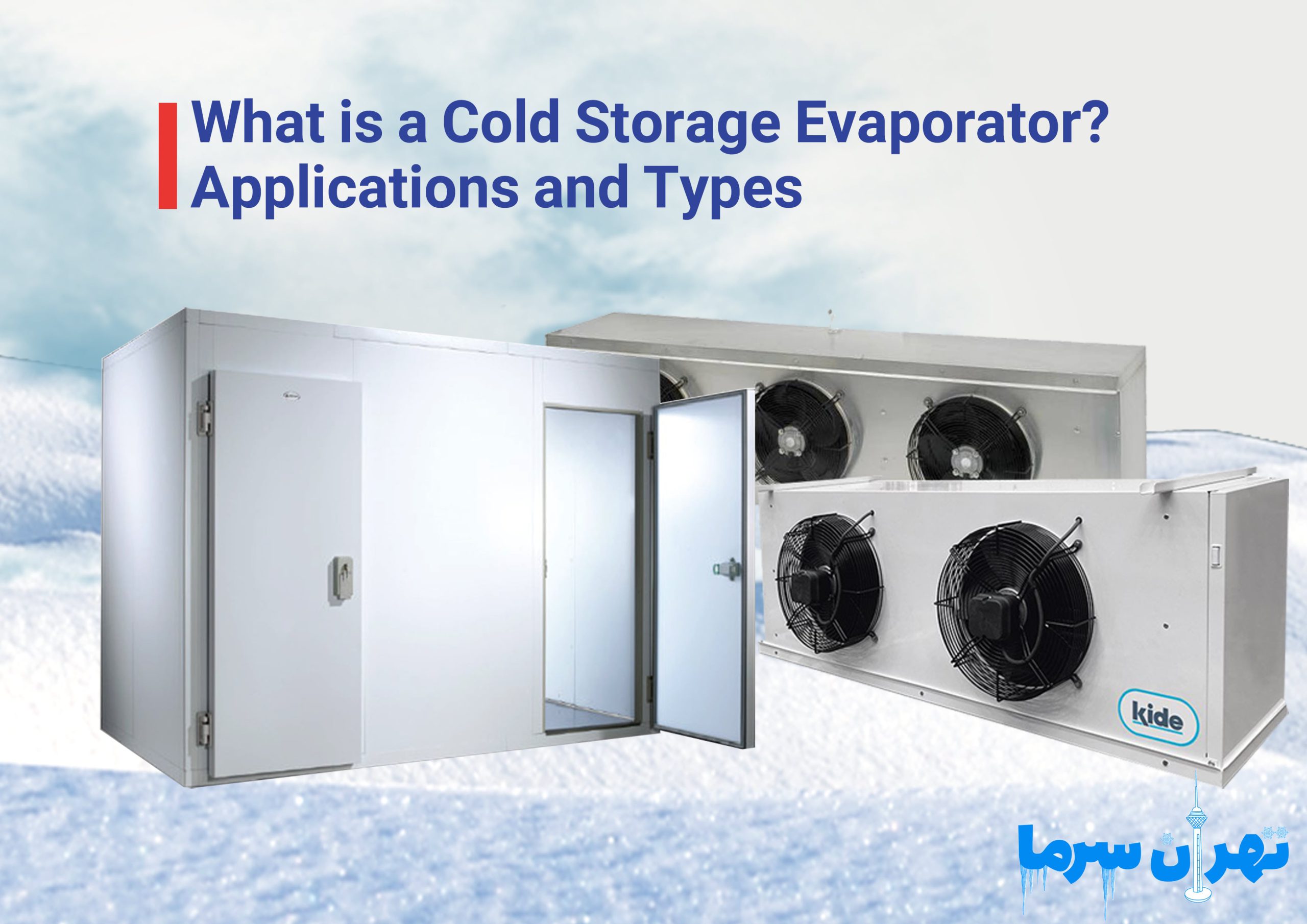

A cold storage evaporator is one of the key components in industrial refrigeration systems, playing a crucial role in maintaining the desired temperature. The importance of the cold storage evaporator lies in its impact on the overall efficiency of the system, as it is responsible for heat transfer and cooling. Therefore, evaluating the performance of the cold storage evaporator in terms of cooling capacity, energy efficiency, and uniform temperature distribution is essential.

A cold storage evaporator plays a fundamental role in the cooling process and the preservation of materials at low temperatures. This component absorbs heat from the internal environment of the cold storage facility and transfers it to the refrigeration system to maintain the required temperature for product quality preservation. By lowering the ambient temperature, the evaporator creates a stable and suitable condition for storing food, pharmaceuticals, and other temperature-sensitive products. Without an efficient evaporator, it would be impossible to maintain a uniform temperature in cold storage, leading to compromised product quality and shelf life.

- Cold Storage Evaporator and Its Types

Evaporators are designed and manufactured in various types, each offering different performance characteristics depending on the specific requirements of cold storage facilities and operational conditions. Common types of cold storage evaporators include air-cooled, water-cooled, and plate evaporators. Air-cooled evaporators are the most widely used in cold storage facilities, utilizing fans to circulate air and absorb heat from the internal environment. These evaporators are typically used for food storage, agricultural products, and pharmaceuticals.

On the other hand, water-cooled evaporators use water as a heat transfer medium and are mainly employed in larger and more industrial refrigeration systems. Another type is plate evaporators, which are used in compact spaces and specialized systems. With high efficiency and small size, they are an ideal choice for certain specific applications.

- The Importance of Cold Storage Evaporators and Their Proper Functioning

The proper functioning of a cold storage evaporator plays a vital role in energy efficiency and the overall performance of the refrigeration system. Factors such as proper design, correct installation, and regular maintenance significantly affect the efficiency of this component. If the evaporator does not function properly, issues such as icing, reduced cooling efficiency, and increased energy consumption may arise, leading to higher operating costs.

Additionally, selecting the right type of evaporator based on the cold storage capacity and environmental conditions directly impacts system performance. For instance, in high-humidity areas, evaporators with an effective defrost system should be used to prevent ice buildup and maintain efficiency.

In general, the evaporator is one of the most important components in the cooling and storage process, and choosing the right one, along with proper maintenance, leads to longer equipment lifespan and lower energy costs. With technological advancements, the development of high-efficiency evaporators with lower energy consumption is expanding, playing a significant role in optimizing refrigeration systems and preserving the quality of stored products.

The Impact of Refrigerant Gas Quality on Cold Storage Evaporator Performance

The quality of refrigerant gas has a direct impact on the performance of the cold storage evaporator and plays a crucial role in the efficiency and effectiveness of the refrigeration system. Refrigerant circulates within the cooling cycle, absorbing and releasing heat to enable the cooling process. If the refrigerant is of low quality, the evaporator’s performance will be disrupted, leading to a decline in overall system efficiency.

Impurities in the refrigerant, such as moisture, suspended particles, and unsuitable oils, can cause blockages in the evaporator’s tubing and reduce heat exchange capacity, resulting in higher energy consumption and decreased cooling performance.

One of the most critical factors influencing refrigerant quality is its type and purity. Using standard refrigerants with stable chemical compositions enhances evaporator efficiency, whereas using counterfeit or contaminated refrigerants can lead to deposit formation and clogging in the evaporator coils. Moreover, moisture in the refrigerant can cause ice formation within the refrigerant flow paths, disrupting fluid movement and reducing cold storage cooling capacity. In some cases, unwanted chemical reactions between the refrigerant and internal refrigeration system materials may lead to corrosion of pipes and a shorter evaporator lifespan.

The choice of refrigerant type is also highly important. Some refrigerants, such as R134a and R404a, are specifically designed for certain temperature ranges, and using the wrong type can significantly reduce system efficiency. For instance, using an unsuitable refrigerant can lead to increased pressure in the refrigeration cycle, placing excessive strain on the compressor and other components, including the evaporator. This not only raises electricity consumption but also shortens the lifespan of parts and increases maintenance costs.

In general, procuring and using high-quality, standard refrigerants is one of the key factors in optimizing the performance of the cold storage evaporator. Additionally, regular inspections to detect potential leaks and remove refrigerant contaminants play a vital role in enhancing efficiency and reducing operating costs.

Given the importance of this issue, using proper equipment for refrigerant purification and recycling, as well as following standard procedures when charging the refrigeration system, can improve evaporator performance and increase the overall efficiency of the cold storage facility.

Methods to Reduce Frost Formation in Cold Storage Evaporators

Frost formation in the evaporator is a common issue that can disrupt the operation of the refrigeration system and reduce cooling efficiency. Ice buildup on the evaporator coils leads to reduced heat exchange, increased energy consumption, and, in some cases, damage to system components. Therefore, implementing effective methods to reduce and prevent frost formation is essential to maintain optimal cold storage performance and avoid additional costs.

One of the most important methods to reduce frost formation is properly adjusting the evaporator temperature and controlling humidity levels inside the cold storage facility. Excess humidity, especially when warm, moist air enters the cold storage space, is a major factor in ice accumulation on the evaporator coils. To prevent this, frequent opening and closing of cold storage doors should be minimized, and proper sealing should be used to reduce air infiltration. Additionally, using plastic curtains or controlled air entry systems can significantly decrease moisture intake.

Another effective method is the use of an appropriate defrost system. Defrost systems are available in different types, including electric defrost, gas defrost, and hot water defrost, each offering specific advantages based on the type of cold storage and environmental conditions. In the electric defrost method, heating elements installed on the evaporator coils provide the necessary heat to melt frost at scheduled intervals. The gas defrost method, which is widely used in industrial systems due to its lower energy consumption, utilizes hot gas from the compressor to heat the coils. In some cases, hot water defrost is used, where warm water is sprayed onto the coils to rapidly melt the ice.

Another effective strategy is proper airflow management around the evaporator. If airflow is inadequate, some areas of the coils may become colder than others, leading to uneven temperature distribution and localized frost formation. Using well-designed fans, adjusting their speed, and ensuring there are no obstructions in the airflow path can help distribute cold air evenly and prevent frost accumulation.

Additionally, selecting the right refrigerant and maintaining the correct charge level play a crucial role in reducing frost buildup. If the refrigerant charge is either too low or too high, it can disrupt the evaporator’s pressure and temperature, increasing the likelihood of frost formation. Regular inspections for leaks and precise refrigerant level adjustments help ensure optimal evaporator performance.

Overall, reducing frost formation in cold storage evaporators requires a combination of control measures, regular maintenance, and proper system adjustments. Continuous monitoring of environmental conditions, routine servicing, checking the performance of temperature and humidity sensors, and using effective defrost systems all contribute to preventing this issue. By following these best practices, not only does system performance improve, but operational costs and energy consumption are also reduced.

Key Parameters for Selecting the Right Cold Storage Evaporator

Several important parameters must be considered when selecting a cold storage evaporator to ensure optimal performance and high efficiency. The cooling capacity of the evaporator must be chosen based on the storage volume and required temperature, as incorrect selection can lead to reduced efficiency or increased energy consumption.

The type of refrigerant compatible with the evaporator is another crucial factor, as each evaporator is designed to work with specific refrigerants. Additionally, the design and material of the coils and fins significantly impact heat exchange efficiency and corrosion resistance. Other key factors include airflow rate, fan power, and the presence of an effective defrost system to prevent frost buildup, all of which contribute to selecting a durable and efficient evaporator.

The Role of Cold Storage Evaporators in Energy Optimization

Cold storage evaporators play a crucial role in energy optimization, as their proper operation directly affects the efficiency of the refrigeration system. Well-designed coils and fins enhance heat exchange and minimize energy loss. Using energy-efficient fans and adjusting their speed based on cooling demand can significantly reduce electricity consumption.

Additionally, effective defrost systems prevent frost buildup, reducing the frequency of compressor cycling, which helps conserve energy. Choosing an evaporator that matches the cold storage capacity and environmental conditions not only enhances system efficiency but also reduces operational costs and extends the lifespan of refrigeration equipment.

Tehran Sarma Engineering Company – Expertise in Cold Storage Construction, Installation, and Repair

Tehran Sarma Engineering Company, with extensive experience and technical expertise, specializes in the construction, installation, and repair of various types of cold storage facilities and is recognized as a leading company in the refrigeration industry. By utilizing cutting-edge technologies and high-quality equipment, this company designs and implements industrial and commercial cold storage solutions tailored to customer needs.

Additionally, the company’s expert team provides regular maintenance and repair services to improve efficiency and extend the lifespan of cold storage systems. Commitment to quality, high efficiency, and energy savings are the key principles Tehran Sarma follows in all its projects.

For more information on cold storage construction pricing and to learn more about our services, visit the Tehran Sarma website or contact us at 09121906418 and 021-77972256.

A cold storage evaporator plays an essential role in cooling processes and maintaining low temperatures. The importance of the cold storage evaporator lies in its direct impact on product quality and shelf life. Therefore, evaluating the evaporator’s performance in terms of heat exchange efficiency, uniform cooling, and energy optimization is crucial for enhancing system efficiency and reducing operational costs.

Source:

https://unitedinsulated.com/

سردخانه

سردخانه برق

برق کمپرسور

کمپرسور کمپرسور بیتزر

کمپرسور بیتزر کمپرسور کوپلند

کمپرسور کوپلند کمپرسور بوک

کمپرسور بوک کمپرسور دانفوس

کمپرسور دانفوس کمپرسور منیروپ دانفوس

کمپرسور منیروپ دانفوس کمپرسور امبراکو

کمپرسور امبراکو کمپرسور پاناسونیک

کمپرسور پاناسونیک کمپرسور سابکول

کمپرسور سابکول کمپرسور کوپلند

کمپرسور کوپلند کمپرسور اسکرال کوپلند

کمپرسور اسکرال کوپلند کمپرسورفراسکلد

کمپرسورفراسکلد کمپرسور رفکامپ

کمپرسور رفکامپ کمپرسور اسکرال دانفوس

کمپرسور اسکرال دانفوس گاز مبرد

گاز مبرد گاز R22

گاز R22 گاز R134

گاز R134 گاز R404

گاز R404 گاز R407

گاز R407 گاز R410

گاز R410 گاز R508

گاز R508 کندانسور هوایی

کندانسور هوایی اواپراتور

اواپراتور اواپراتور آرشه

اواپراتور آرشه اواپراتور صابکول

اواپراتور صابکول اواپراتور آسه

اواپراتور آسه اواپراتور نیک

اواپراتور نیک اواپراتور آرتک

اواپراتور آرتک اواپراتور نوین

اواپراتور نوین اواپراتور تبادل کار

اواپراتور تبادل کار درب

درب ساندویچ پنل

ساندویچ پنل فن سردخانه

فن سردخانه روغن کمپرسور سانیسو

روغن کمپرسور سانیسو متعلقات سردخانه

متعلقات سردخانه